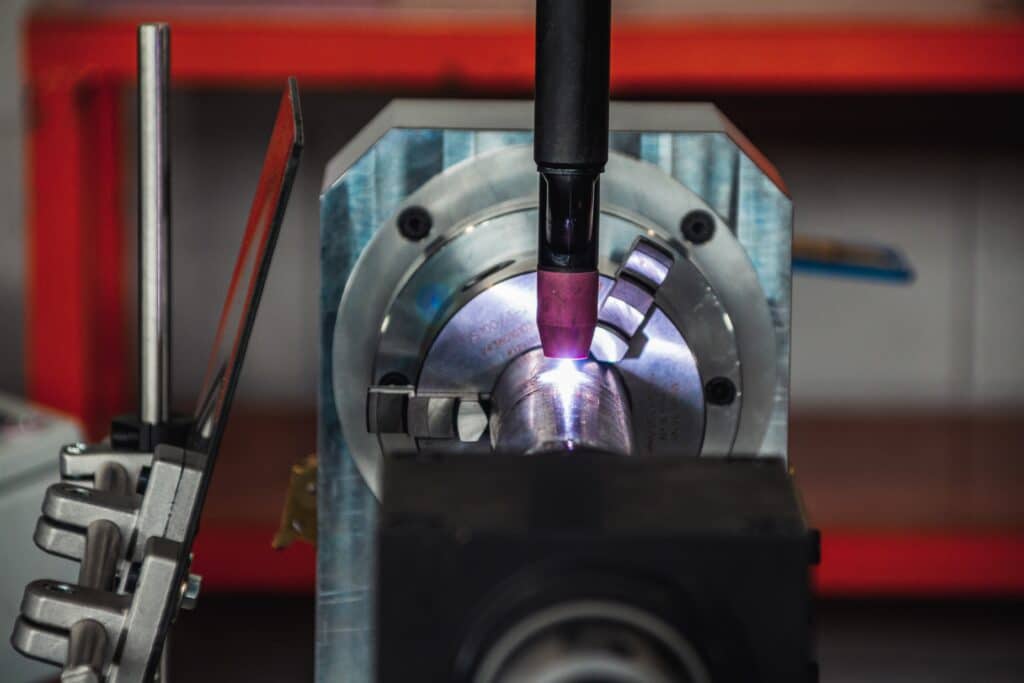

Medical designers have a lot of opportunities when they leverage the power of laser welding technology to create distinctive and innovative devices and tools in the healthcare sector.

Some alloys and metals are impossible to weld using other welding methods to create surgical or dental instruments that require high precision. So, laser welding has helped explore new alloys and metals with precise cutting to provide optimal union of medical device components.

The healthcare sector is demanding improvements, resulting in the innovation of new medical devices. Manufacturers and designers are looking for new ways to use materials to achieve smaller forms and speed up the delivery of various medical parts.

This article will expound on multiple machining tips medical designers can use to create disruptive ideas.

Laser welding utilizes a small portion of the material to create durable markings compared to screen printing. This makes it an easy and understandable concept in medical welding when identifying marks crucial in protocols. This is crucial, especially for long-term implants, reusable devices, instruments, or tools.

You do not need to use flux to weld two materials. That means there is less risk when introducing a new material. For example, you cannot risk adding a material to a bio-implant leading to no harm. Additionally, laser markings don’t need the use of pigment.

Therefore, there are fewer chances of contamination.

The good thing about laser welding is that its output is controllable, making it advantageous for welding, marking, and cutting delicate components. Additionally, the heat produced from the beam stays in one place called the HAZ, or affected heat zone.

That means there are fewer chances of damaging the adjacent areas. Its programmable and precise power output gives control over the depth of the beam in the material, also known as the z dimension.

The key to creating quality medical devices is the capability of always turning out machines in the same dimension. Because of their high controllable power in position and temperature, laser welding provides high repeatability.

As mentioned, it is easy to control the beam’s position because of its precision. This is crucial in creating medical devices where tolerance is required in a small area. The XY control is vital as the devices become smaller and the contours and shapes become more intricate.

The ability to control temperature, position, and programmability, even in new and intricate designs, provides faster turnarounds. That makes it convenient for companies like Micro Weld, Inc. and other medical innovators to develop prototypes and take advantage of the smaller market opportunities.

The key to manufacturing quality medical devices is considering the level of value a laser service provider brings to the table before outsourcing. Check if they have a proven track record of demonstratable success in healthcare.

The laser service provider you outsource should also demonstrate their commitment to updating technology. Keeping up with technology advancements in laser technology is not easy, but a good service provider should verify that they are willing to continue adjusting to changes.

If you are interested in even more business-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

Companies generally look for people with expertise in technical skills, but the hospitality industry also…

Esports has transformed from a niche pastime into a global phenomenon, with millions of fans…

Marketing has historically been focused on what you can tell your audience— how you can…

Do you ever get so busy taking care of everyone and everything else that you…

The Bitcoin price in USD has fluctuated steeply over the past month, from a high…

The online gambling industry has expanded rapidly, offering players around the world the ability to…