If you’ve embarked on the journey to becoming a good product designer, one of the first things you’ll learn is that there’s a vast difference between designing a product and manufacturing it. Product manufacturing involves multiple moving parts; you’ve got to find the right equipment supplier, and you need a solid printed circuit board (PCB) manufacturer.

A PCB manufacturer will produce your PCB circuit board to your exact specifications and consistently deliver high-quality boards. Assuming you’ve created a tech product, one small mistake in your PCB could flaw the entire product. And chances are not just one product will have defects, but a whole batch of them.

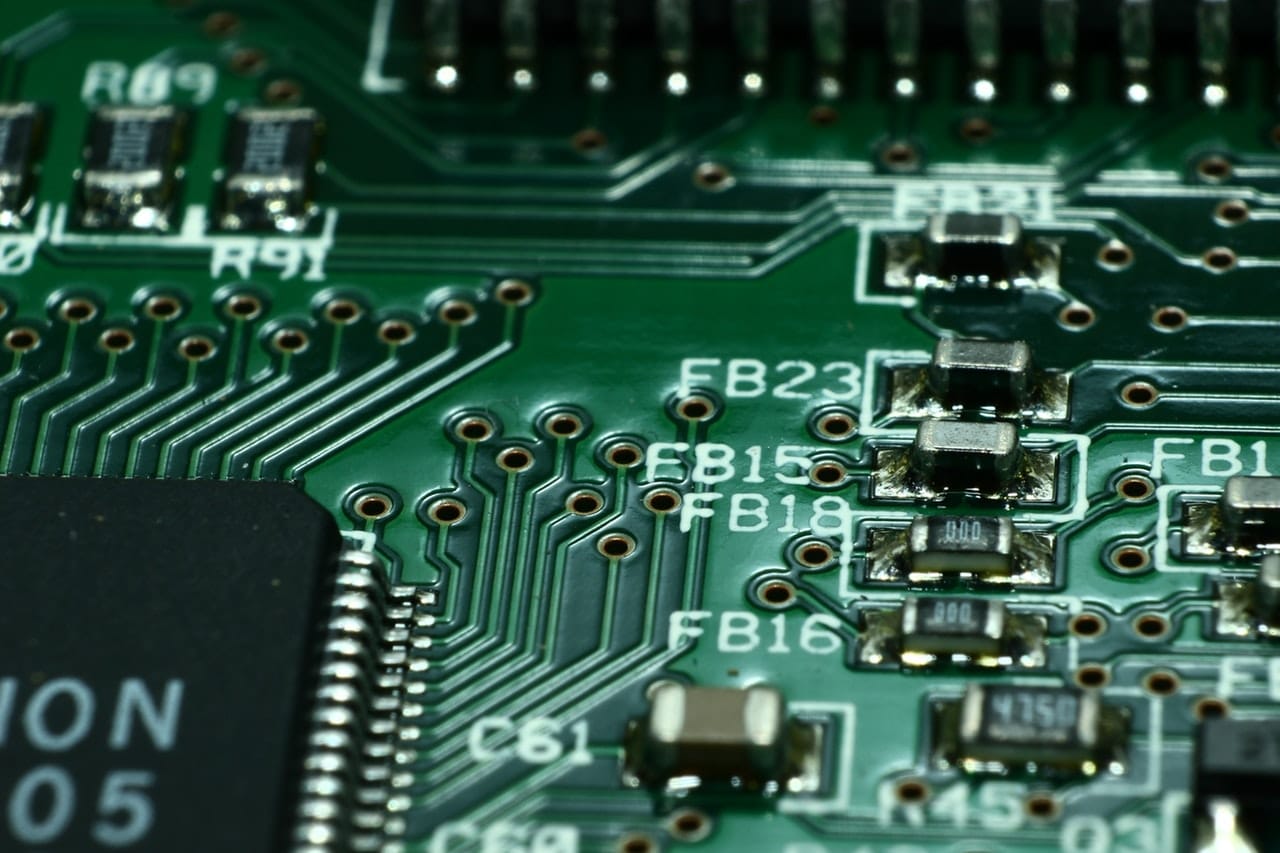

Your circuit board is the foundation of your product; it’s what drives it and makes it work. But with thousands of PCB manufacturers out there, knowing how to choose the right one can complex. With that in mind, here are five questions you should ask every potential candidate as you scout for the best options:

IMAGE: PEXELS

What Certifications Do You Have?

Understanding a manufacturer’s certifications can offer valuable insight into the quality of the work they produce. Many manufacturers simply say that they are compliant and have proper certifications, but they haven’t taken official, mandated steps to become legitimate in certain areas.

For instance, ISO is a set of quality management standards that operate with stellar efficiency. UL is a listing service that requires rigorous testing of products, and RoHS (Restrictions of Hazardous Substances) is a set of restrictive laws that prohibits the use or presence of six primary hazardous substances during the manufacturing of electrical equipment.

2. Where Are Your Materials Sourced?

Manufacturers that offer low-priced circuit boards with super-fast turnaround times tend to source their materials from cheap outlets, which could ultimately affect the quality of your own product. For instance, certain low-level materials, like laminate, still need to be sourced from high-quality vendors.

Although the majority of PCBs use the same pool of materials, if they use cheap substitutes, you could find your product integrity compromised. Furthermore, you want to ensure that they’re using the same high-quality materials consistently, rather than switching material sources after initial production.

3. What Is The Turnaround Time?

Understanding what you expect from your turnaround time will help you make better decisions about who to choose, though you should also know that faster turnaround times are also associated with higher costs. If you can avoid rushing to market, you should. Think about your long-term strategy.

Many new product designers struggle with realistic ideas of production because they want their product out into the world as soon as possible. If this is what you want, you’ll need the budget and the strategy to make it worth your while.

Considering the turnaround time, it’s also essential to think about how accessible the manufacturer will be to you when you need them. While it’s not necessary for them to be available to you at the drop of a dime, it’s still essential that you be able to access them when the situation calls for it.

It’s also vital that you work on getting your patent before you start to talk to manufacturers. In the past, many manufacturers have gone on to take credit for work they didn’t design, and you can avoid a headache by going through the proper steps to ensure you’re always credited as the rightful inventor.

4. What’s Your Track Record?

Any time you work with a third party company, you want to know that they’re capable of producing the work, and have a track record to prove it. But it’s also important to note that even companies with strong track records may not have experience with products like yours, especially if you’ve created a product that doesn’t have much competition on the market.

In the later case, there’s a bit of wiggle room to take advantage of a new manufacturer that doesn’t have a strong track record, but you should proceed with caution in this case. If you take a chance with a new, competent track record, both you and the manufacturer could make a splash in your industry—and you’ll benefit from cost savings as well.

5. What’s Your Customer Service Like?

While many PCB manufacturers do not have dedicated customer service teams, you’ll want to know early on how the company handles communication with you, especially if there are language barriers or larger time zones to consider. Ask them what’s the standard turnaround time for answering questions, and what’s the potential for setting up virtual or in-person meetings.

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS