3D printing (also known as additive manufacturing) is making inroads into various fields including agricultural (such as tractor parts), industrial, civil engineering, aerospace, and medical equipment manufacturing. But as with any positive development, there are risks.

For additive manufacturing, it’s the fact that the printers are usually connected to the Internet and often open-sourced. There’s also the growing use of manufacturing-as-a-service (MaaS) where a vendor leases out their 3D printing infrastructure to multiple manufacturers whose only role is to transmit their complete designs.

All this exposes additive manufacturing to a number of cybersecurity risks. The following are the key cybersecurity challenges that 3D printing faces today.

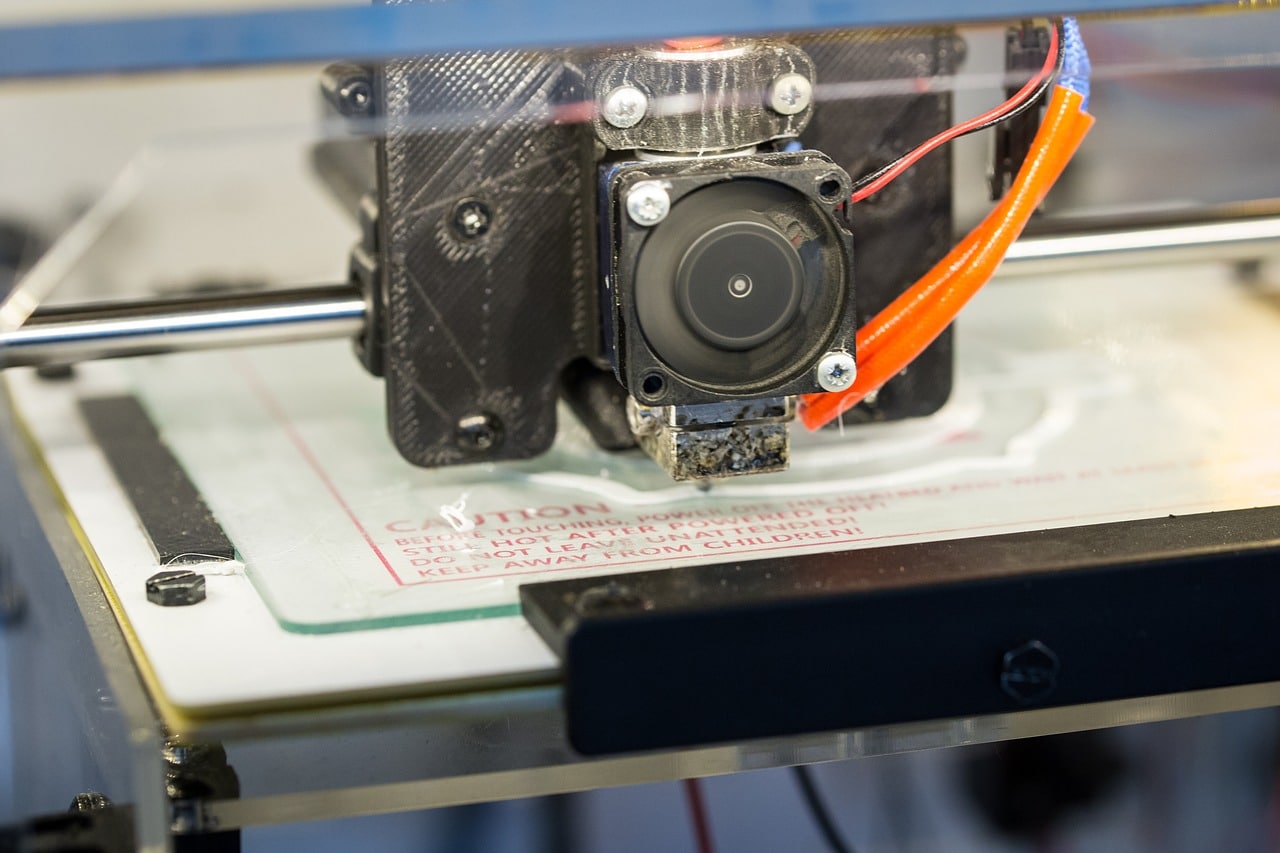

IMAGE: PIXABAY

Just like conventional manufacturing, any company that taps into additive manufacturing has a commercial end goal. The 3D printing is meant to create a product that’s better and more affordable than what’s available from the competition. The product’s design is at the heart of this competitive advantage.

If the design falls into the wrong hands (in this case a competitor), the IP owner stands to lose future revenue. For context, think about how the entertainment industry has been deprived of billions of dollars over the years thanks to the availability of P2P file sharing tools.

If an unauthorized person does access a product’s 3D design, they could proceed to print a counterfeit version. This is already bad enough because it means they’ll illegitimately receive revenue that would otherwise have been accrued by the design owner.

Even worse though, there’s no guarantee that the unauthorized party will use the required input materials when printing the product. If they use an inferior quality material, this could affect your brand’s reputation since buyers may not know that what they have purchased is not the original.

Once the security of the design is compromised, it clouds the traceability of the 3D printer output. Did the printer receive the latest transmitted design and was the right material used? There’ll be doubts about the authenticity of the product if there’s no certainty about the unbroken connection between the physical item and the digital design.

A manufacturer bears liability for any defect in their product. That includes design, manufacture and foreseeable misuse defects. If the integrity of the digital design (whether at rest or during transmission to a vendor) is not assured, the loss of data and production control could lead to product defects and misuses.

A hacker could sneak in design changes that have dangerous and/or costly real-world consequences such as deaths, injuries, property damage and product recalls. The manufacturer will have to bear the costs of this defect liability even though they were not the one responsible for introducing the defect.

Some of the data that’s relayed as part of the product design may be private and confidential. For example, a part that’s being produced for a particular company will likely need the company’s name or brand hard-printed on the product itself. It will, therefore, be a part of the design sent to the 3D printing vendor.

In the absence of the brand or owner name, someone who illegally intercepts the design during transmission won’t know who it’s meant for. If they discover who it belongs to, they can sell the design idea to a competitor via the black market or proceed to build their own version and rush it to the market before the original is officially rolled out.

These risks have been top of mind for both the leadership of additive manufacturing companies and cybersecurity professionals. Fortunately, there are a number of ways one can mitigate against these risks and ensure the product design is secure during transmission to the 3D printing vendor.

For instance, a team of researchers developed a triple-layer system that uses printer component tracking, acoustic measurements, and detectable nanorods to establish that the design hasn’t been compromised. Another technique you could use if you have to send product design to the 3D printing vendor via the Internet is to encrypt and secure the data packets using a virtual private network (VPN). Cybersecurity is an inseparable component of additive manufacturing. Companies that fail to recognize these risks and take appropriate steps to mitigate against them are in danger of negating the production advantages that come with 3D printing.

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

IMAGE: PIXABAY

Warehouses are changing fast, pushed by rising demand, tighter safety standards, and the constant shuffle…

Cybersecurity is no longer a task for governments and large corporations in the connected world…

Fame is a powerful force that extends beyond a celebrity’s lifetime. Icons like Marilyn Monroe,…

In an era where sustainability, transparency, and corporate responsibility are paramount, businesses are under mounting…

In today’s fast-paced and competitive business environment, managing intellectual property (IP) is more crucial than…

Working in tight or confined spaces is one of the most common challenges in modern…