The main purpose of any cooling tower is heat loss into the atmosphere and the crossflow cooling towers follow the same idea. Crossflow is one of the main wet cooling towers. This cooling tower is used in Heating Ventilation and air conditioning (HVAC) systems and also large scale cooling and air conditioning systems. The cooling tower works by crossing air vertically against water horizontally hence the name “cross-flow”. Visit Sara Cooling Tower, you can get more information about the cooling tower.

IMAGE: MWT

The Concept

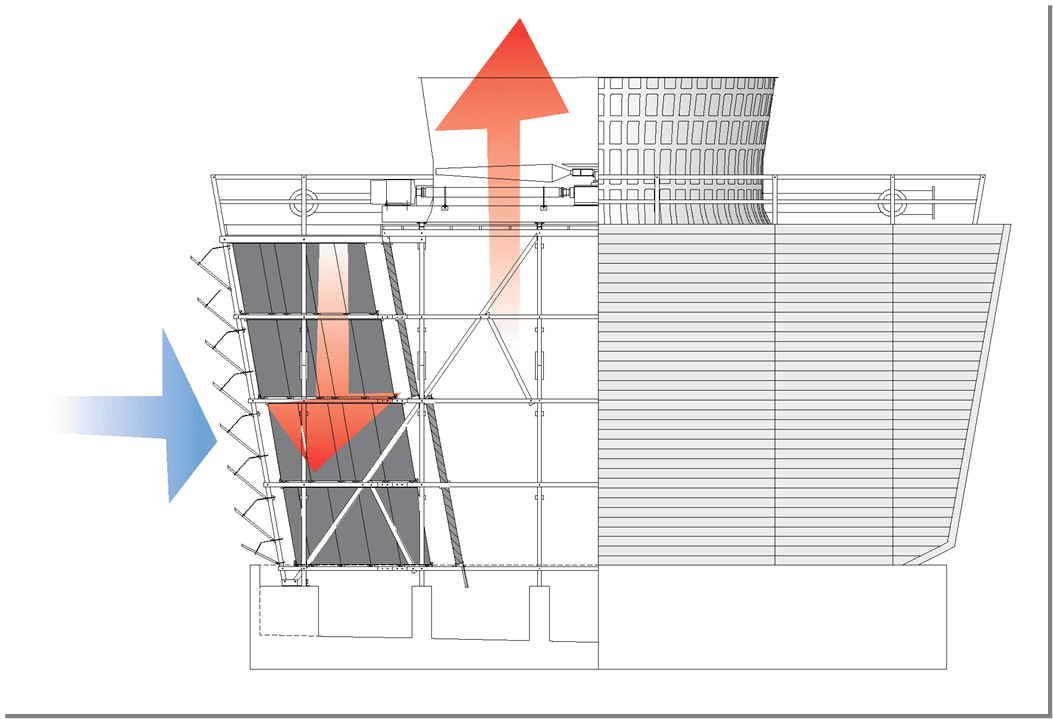

Crossflow cooling tower works by allowing the water to flow vertically through the fill while the air horizontally flows across the water via the louvers. The hot water flows in by gravity while the cold air cross or rather flows across the tower and gets in contact with the water and the resulting in cooling.

The air doesn’t have to come in via the distribution system. Permitting the use of gravity by the hot water flowing into the basin mounted at the top of the unit above the fill. The drift comes out through the top and the make-up water is allowed to flow in to level the water in the basin. The precise level is determined by the float ball.

Space Requirements

Crossflow cooling tower requires more plan area hence are more suitable for areas with lower population and more space is available.

Maintenance

Crossflow cooling tower has a larger plenum area allowing access to the cooling tower. This makes the inspection, repair, and maintenance very easy.

Water Distribution

Here water is pumped to the top of the tower and discharged into a hot water basin with nozzles. The process is dependent on the gravitational force.

Variable Flow And Cold Weather Operation

Water distribution affects the variable flow and cold weather operation directly. The crossflow tower can utilize as little as 30% of the design flow and maintain even water distribution across the fill. During cold weather, the use of nozzle cups on the inboard side keeps the heat towards the side of the fill exposed to the cold or snow.

Tower Material

The material used includes galvanized steel, stainless steel, glass fiber, and concrete are commonly used. Plastics are widely used for fill including PVC and polypropylene. Treated wood splash fill is still used to this day when water conditions demand the use of splash fill. Nozzles are currently made of PVC, ABS and glass-filled nylon. Fans are made of galvanized steel, aluminum, or molded glass fiber reinforced with plastic.

Components Of The Crossflow Cooling Tower:

- Spray nozzles; when water comes in and fills the space given it drains down via spread out holes to the spray nozzles. They enable the water to spread out over a large area.

- Fill; from the spray nozzles, water drains. It’s mostly hexagonal in shape and water flows down due to gravity.

- Basin; the reservoir of the cooling tower. All the water drips down to it.

- Fan; It is on the top of the cooling tower and supplies cool air into the cooling tower.

- Air inlet; the air passes through and goes in the cooling tower.

- Louvers; the main role of this part is to keep off unwanted bodies from the cooling tower like rodents or birds. It also prevents splashing.

- Drift Eliminator; air goes in past the louvers, fill to the drift eliminator. It allows the evaporated water to pass through.

- Drift; this is not a cooling tower part, it is the representation of water loss. The more drift you have the more water is lost which is expensive.

- Float; it regulates the water coming in to replace the lost water as drift. It opens and closes depending on the level of water in the basin.

- Makeup water inlet; this is the water coming in to replace the evaporated water.

- Water outlet; the way in which the cooled water leaves for circulation.

- Overflow; get rid of the excess water in the cooling tower basin.

- Drain; this part is really important as it is used to control the amount of concentration like the salts and any sediments that have accumulated over time at the bottom of the tower.

If any of the cooling tower parts broke, faulty or simply worn out you should come and shop at Sara Cooling Tower. Our products are pocket-friendly and of great quality. Our company’s cooling tower products are being used widely around the world.

Pros Of Crossflow Cooling Towers

- The design allows for a large plenum area which allows an access door making it possible to inspect the cool water basin.

- Has room for mechanical access platforms allowing cleaning and repair.

- Crossflow cooling tower because of its reliance on gravity it allows both low flow and high flow of the hot water.

- Best for cold weather operation as there is even distribution of water on the fill. This prevents ice formation which can damage the tower.

- Has integral louvers to the fill keeping any splash-out.

Cons Of Crossflow Cooling Towers

- Requires more space to set up.

- Has fewer air inlets compared to counterflow cooling tower.

Factors Affecting Crossflow Cooling Towers

The Crossflow Cooling Tower Work Is Affected By:

- Heat loss and circulation flow is not all that is required for great cooling tower performance. Flow rate is a major contributor as it affects how the cooling tower works.

- The rate at the exchanger is determined by the heat load and the water circulation rate through the exchanger and on to the cooling water.

- Cold temperature 32.20 The cold weather affects how the cooling tower works as water let down to the filler is affected and there is a high chance of solid formation. The solids affect the running of the tower.

- Heat load. The heat load on the cooling tower is determined by the process by which it is dished out. The degree of cooling required relies on the operating temperature of the process. The size and cost of the cooling tower is proportional to its heat load.

Cooling towers are a productive way of getting rid of heat, cooling systems, and air conditioning. The crossflow cooling towers work perfectly in well-spaced areas. If you are planning on buying parts for your cooling tower visit us at Sara Cooling Tower, you need it we got it!

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS