With 2018 ending and commencing into a new year, most of the industry heads are looking forward to witnessing how the latest technological evolution of the printers will turn its path. Innovations are on one side and that happened decades ago, but since then, the printers have evolved to a point where they are capable of printing the three-dimensional figures of the picture fed into the system.

3D printers have seen it’s fair share of trends in 2018 without a doubt, be it in the types of filaments used or in the kinds of industries where the 3D printed objects have started dominating over others. Benefits are abundant, and so are the applications, but that’s not all which are being expected in this 2019 year.

So, here are the latest trends which are expected to change the 3D printing industry, albeit for the good in 2019.

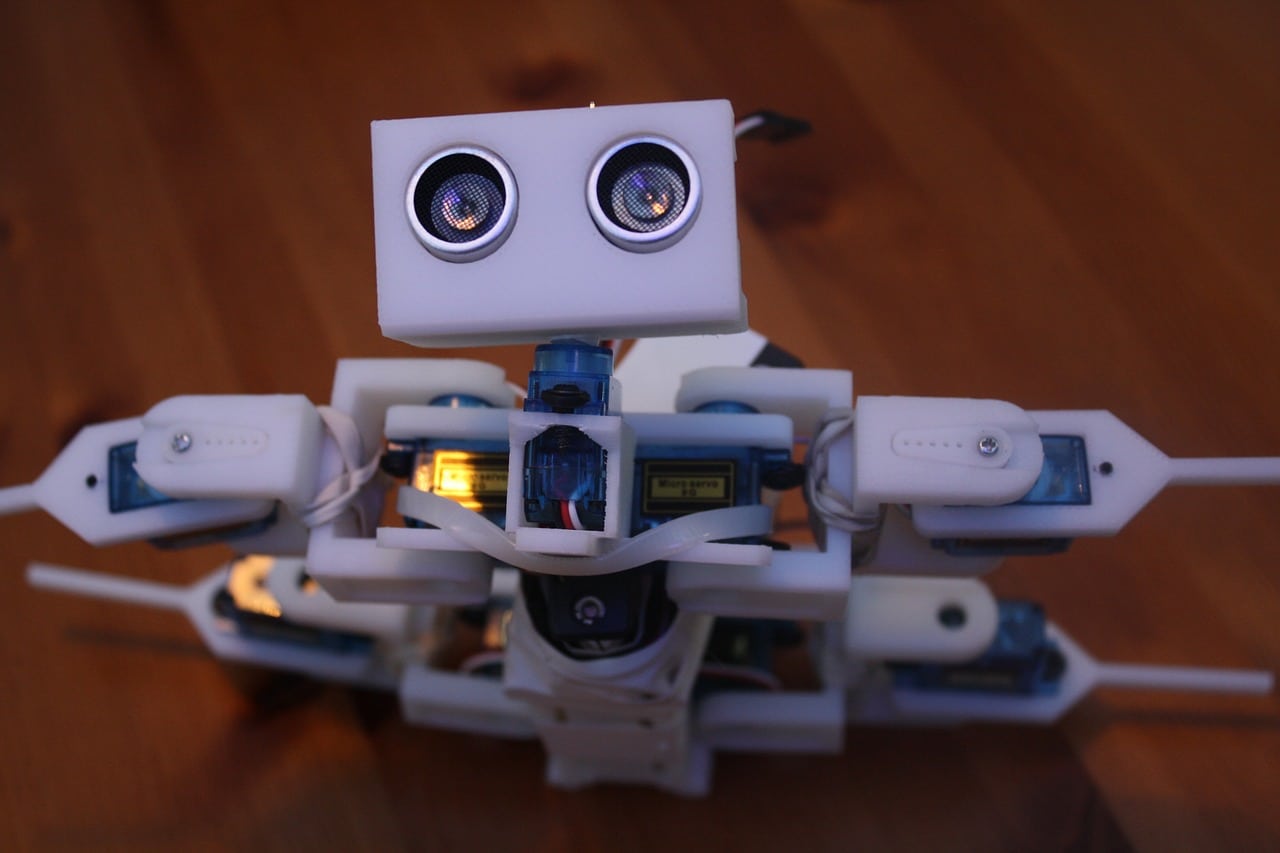

IMAGE: PEXELS

Though 2018 has seen a dramatic increment in types of filament materials, starting from the inorganic to the organic polymers, resins, and so on, it is time to shift towards a more reliable source of 3D printing material- metals. Metal additive manufacturing is becoming one of the flourishing industries, as the metal filaments are already being in use for the production of lighter materials. Also, Aluminum can be hard to drill, despite its easy rep.

Changes are being introduced to the design of the 3D printers in order to make it faster, thereby increasing the production rate. The vibrations between the parts of the printer were one of the causes of the quality degradation and speed reduction. However, scientists from the University of Michigan designed an algorithm which will decrease these vibrations, thereby increasing both the quality and the speed.

With being smart we mean being digital and well-connected. As the market is evolving, so is the technology and it is expected that in 2019, the manufacturing process will witness an automated form of marketing, which will be more digitalized.

Though not in use, plans are being made for making the post-processing methods automated. Till now, the post-processing methods are all manual, and as a result, they are giving the workers a serious headache. Not only the process is hectic, but it also requires a lot of time which in turn is increasing the production time. That’s why many companies like PostProcess Technologies and Rosler are trying to establish automated processes for increasing the manufacturing process.

Without the proper simulation of the entire printing model, great success can be achieved in the industry. The incorporation of proper simulation software into the hardware of the 3D printers will help you to overcome the obstacles in the design and the manufacturing of the sketch into a 3D figure. In 2019, software used in the printing process will scale the manufacture, automate the tasks to a greater extent, and will control the quality.

The use of the 3D printers in the medical industry was seen in 2018 also, where different parts of the body were designed with the printer. Starting from prosthetic masks to the metal joints, the medical industry has openly accepted these 3D printed materials for the purpose of advancements. Now, it is clearly expected that in 2019, the medical industry will witness more innovations. As for the aviation, the lightweight metal printed parts will soon replace the counterparts of an aircraft, making it light and durable.

Customizing the 3D printed parts to satisfy the needs of the customers is becoming the top priority of various companies who are looking forth for mass production. Adidas and Nike have already established the customization process in their works, thereby using the 3D printers to produce the objects at a large scale. The best part of the customization process is that the companies can focus on a user-oriented manufacturing market rather than the sales-oriented market.

As the population is getting familiar with the probable benefits of the 3D printers, it is becoming possible for the industries to teach many about this new technology. So, without a doubt, 2019 will mark the beginning of an expertise area where more and more employees will start learning about this thriving technology.

As the printers will witness up-gradation, the price of various 3D printers will definitely increase. So, when you will walk into the store to buy one, it will be mandatory to compare 3D printers and choose only the best one for you.

Without a doubt, polymers have found it’s extensive use in the 3D printing industry. In the initial days of this technology, resin filaments were used which had it’s own pros and cons. But to refine the quality of the prints, polymers were added to the list, where various organic compounds were mixed to obtain the desirable filament.

Expectantly, 2019 will witness further divergence in the polymeric filaments, with higher print quality. Apart from the rise in the applications, scientists are expecting a lot from 2019, some are just the improvement in the existing trends from 2018, while some are expected to be brand new trends, one which we never expected to have happened.

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

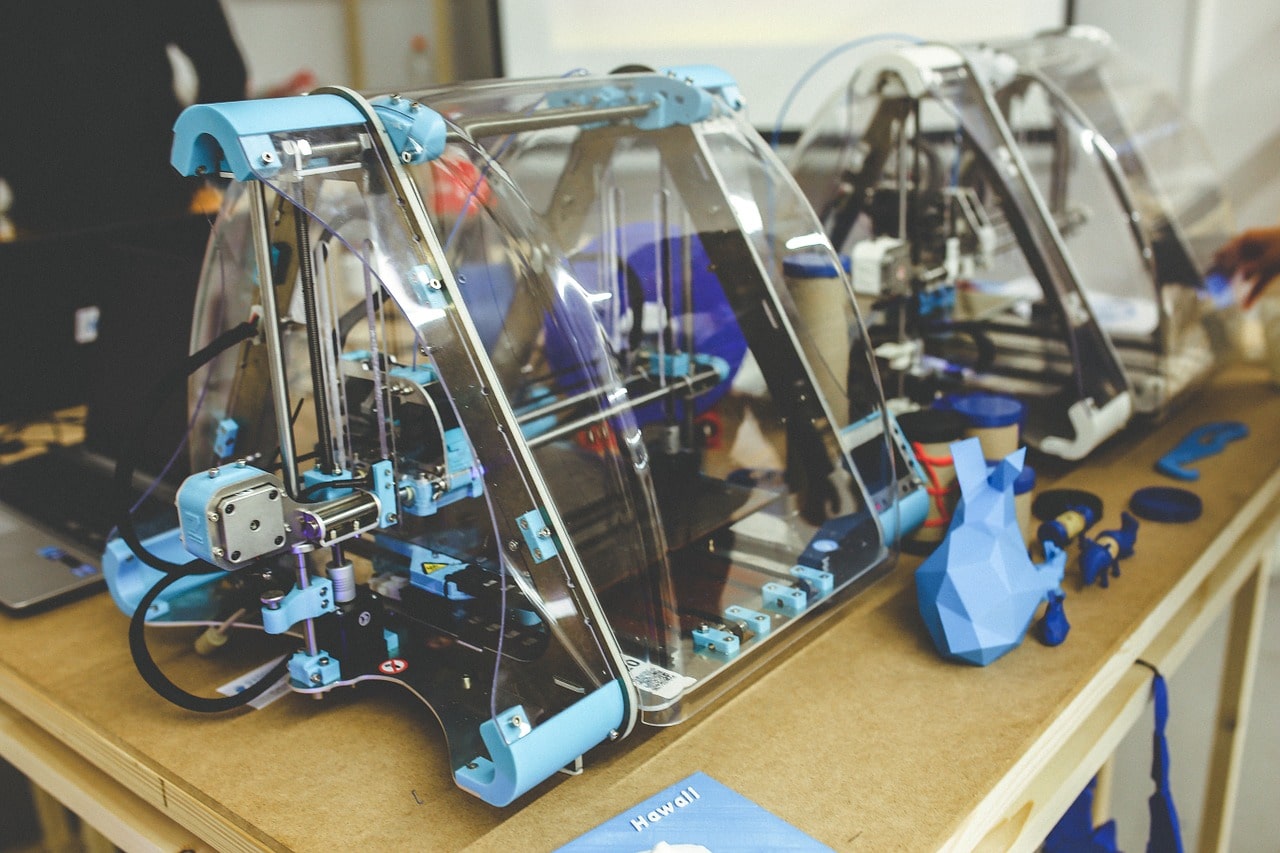

IMAGE: PEXELS

Warehouses are changing fast, pushed by rising demand, tighter safety standards, and the constant shuffle…

Cybersecurity is no longer a task for governments and large corporations in the connected world…

Fame is a powerful force that extends beyond a celebrity’s lifetime. Icons like Marilyn Monroe,…

In an era where sustainability, transparency, and corporate responsibility are paramount, businesses are under mounting…

In today’s fast-paced and competitive business environment, managing intellectual property (IP) is more crucial than…

Working in tight or confined spaces is one of the most common challenges in modern…