Many industries rely on specialized equipment or machinery. To explore some types of machinery and their individual capabilities, let’s explore CNC Machines and industrial filtration equipment.

IMAGE: MW WATERMARK

CNC Machines

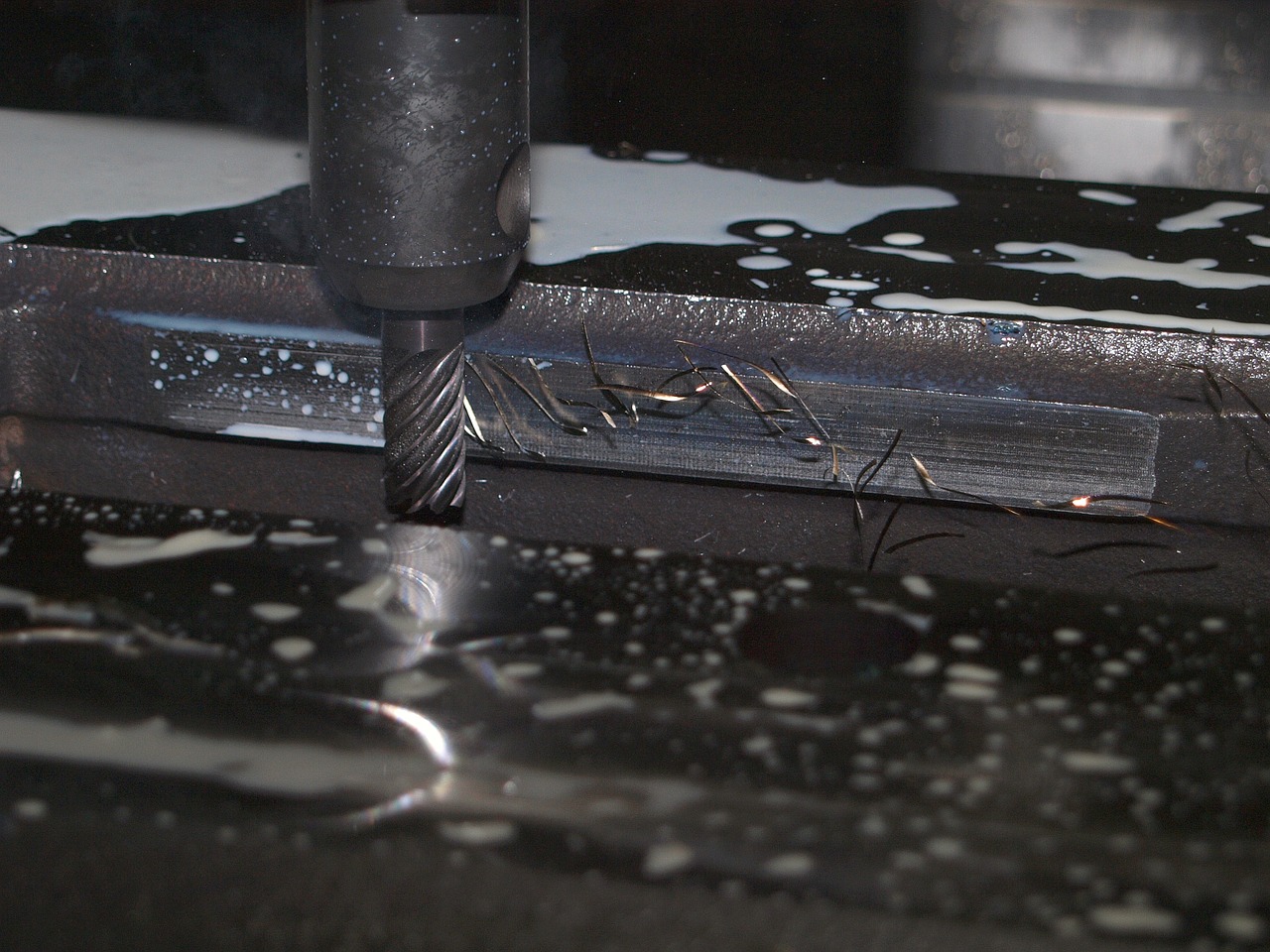

CNC stands for Computer Numerical Control. CNC Machining is a process of manufacturing that uses computers to control machine tools. Making use of lathes, mills, routers, and grinders, the computer’s unique software and control console use the numerical control to function. A computer program is customized, the machines are programmed with G-code (CNC machining language) and an object is customized so that the computer essentially controls all features like feed rate, coordination, speed, and location, exact position, and velocity.

CNC machining is used in manufacturing metal and plastic, by working off a 3D or 2D drawing to create a code. Once the program is loaded and tested, the machine can begin making the product on its own. Perfect for high-level precision and very repetitive tasks, CNC machines are the future of high-tech business. They can be purchased from providers like CMS North America, Inc.

Industrial Filtration Equipment

Filtration equipment is used in hundreds of industries, and it saves businesses (and the planet) billions every year. Used in heavy machinery as belt filters, drum filters, vacuum belt filters, and more, industrial filtration equipment has uses in the car wash, laundry, oil, lime softening, and concrete industries. In the car wash industry, an industrial filter press will save 10-15 gallons of water per car by recycling 50% of the water used. Since roughly 2.3 billion cars are washed annually, that’s a lot of water (and a lot of money) saved. Likewise, in the laundry industry, since water is 50% of the operating cost, filtration saves impressive dollars each year by cutting the water wasted by up to 7.5 gallons per load.

Other uses of industrial filtration equipment include hydraulic oil and fracturing gas. US industries use between 70-140 billion gallons of water each year, and filtration equipment can recycle anywhere from 10%-70% of that water. The lime softening business relies on filtration equipment to remove pounds of sludge from the water every day. Likewise, in the metal finishing industry, filtration equipment allows 50%-75% of water to be reused.

It’s fascinating to learn about the many uses these machines and equipment have. Replacing menial, dangerous, or low-paying tasks, CNC machines are a valuable business innovation, and are now available for small companies. Filtration equipment saves billions of dollars each year in respective industries, making it an extremely valuable installation, both for businesses and for the world.

If you are interested in even more business-related articles and information from us here at Bit Rebels then we have a lot to choose from.

COMMENTS