PCB boards are, without a doubt, one of the most monumental tools of mankind. Why? Because PCB boards are in almost every single electronic device in the world today. Here are 10 interesting facts about them.

IMAGE: PEXELS

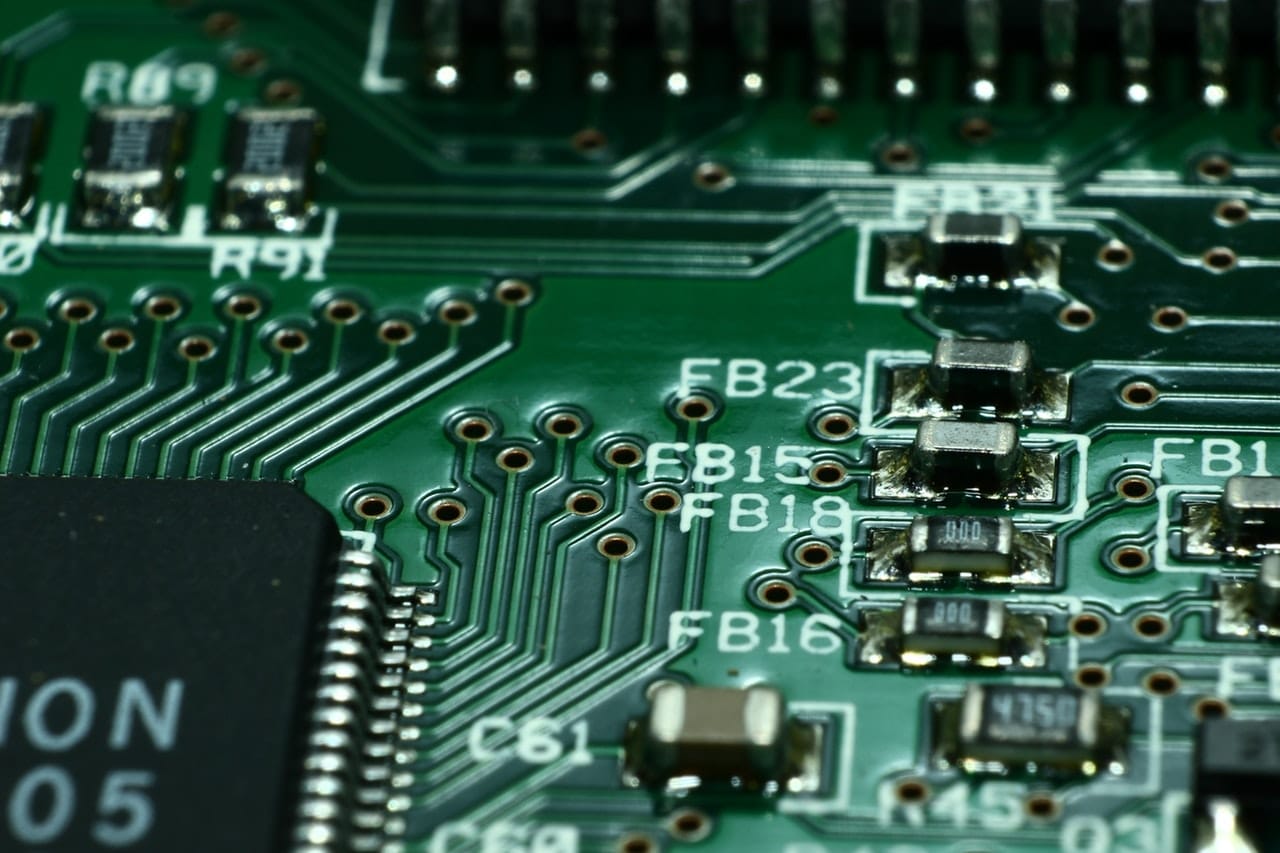

1. Colour

Even people who don’t know what they are (or what they’re used for) know what PCB boards look like. These boards are iconic least of all because of their green color, which is actually the solder mask shown through the glass. The majority vote is that green was the military-regulation standard (when the military initially used them). These days, however, PCB boards are printed using a variety of colors, as green is not the industry standard.

2. Precursor

Using ink to conduct electricity (and printing brass wires on a board), Charles Ducas put out a patent for a “printed wire patent”. Sometime in the 1920s, he managed to create a prototype of the PCB board and electroplating: an insulated surface that directly held an electronic path.

3. Markings

The green PCB solder mask that we see is beneath strange white etchings. For years, people didn’t know how to make heads or tails of these – which is called the “silkscreen.” On PCB boards, the silkscreen helps identify components as well as other information as it relates to the PCB. Once printed by silk screen, hence the name, it is typically printed by ink-jet printers. Typically, it allows engineers an easier chance for them to see if there are any problems on the board.

4. Invention

Many people know that Austrian inventor Paul Eisler is credited with the invention in 1936. Which makes it sad, given the fact that the invention has its roots in the 1890s. What’s even more astonishing is how at the time he devoted most of his attention to developing a radio.

5. Production

The auto-assembly process (responsible for creating more PCB in a fraction of the time) is because of the Army Signal Corps – who undoubtedly needed the technology as soon as possible, for obvious reasons. Once production of these boards increased, popularity boomed.

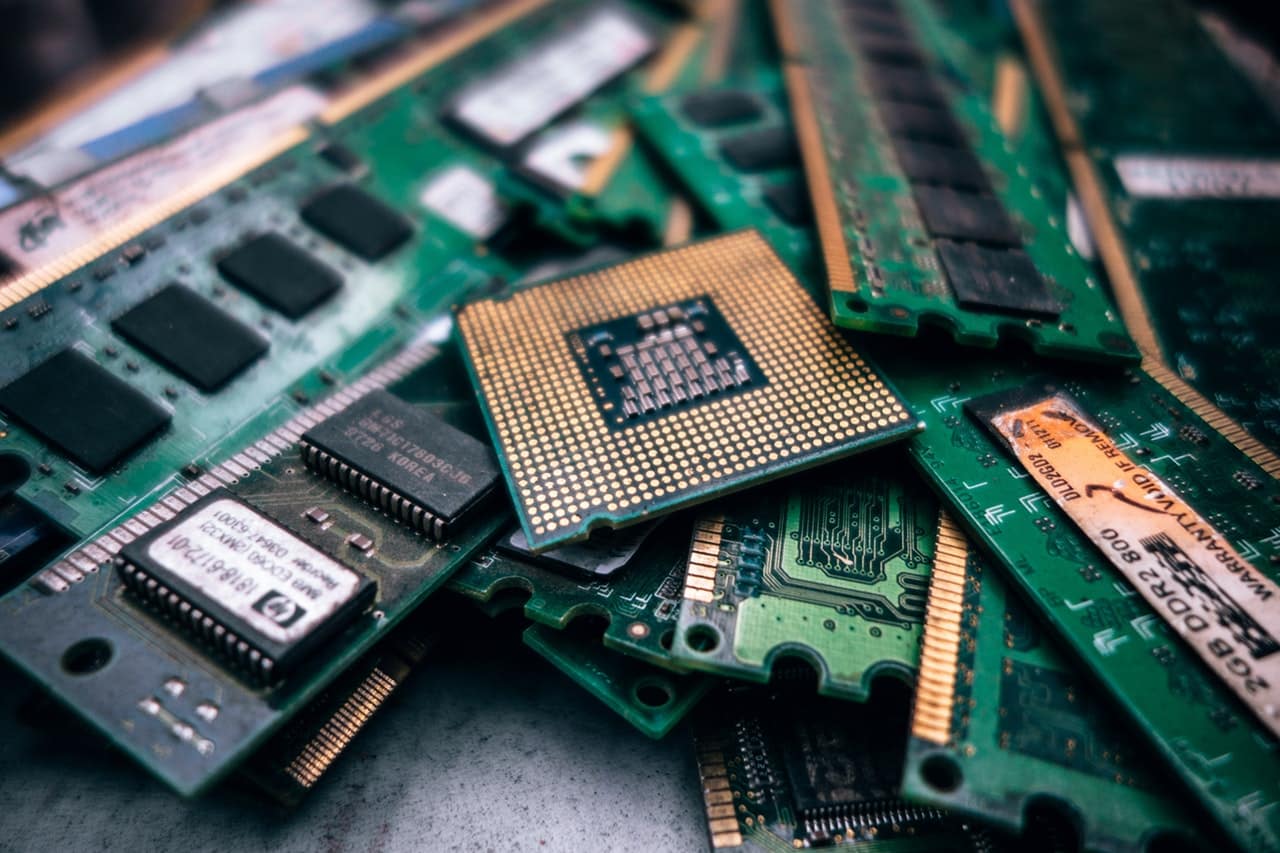

6. Components

Each component contained inside a printed circuit board has its own property, as distinct and varied from the component next to it. These components include resistors, diodes, transistors, capacitors, relays, batteries, transformers, and a lot more (including fuses, inductors, potentiometers and a lot more).

7. Popularity

PCBs are everywhere. That’s no exaggeration nor hyperbole. From computers to digital clocks, microwaves, TVs and stereo systems: if it is an electronic appliance or device, chances are 99% that there is a PCB board inside it. This can make them easy to take for granted, considering without them our devices wouldn’t run.

8. NASA

Imagine creating something so ground-breaking that NASA uses it. In the 60s, NASA used PCBs (due to its significant lightweight and minimal electricity requirements) in Apollo 11 – the rocket that astronauts used to land on the moon. A great day for mankind.

9. Surface Mount Tech

SMT is a manufacturing technique used to make modern PCBs. This technique replaced the through-hole method, via inserting component “leads” into holes – hence the name. This process was time-consuming. SMT, on the other hand, takes a fraction of the time as components are glued onto pads.

10. Software

Before being physically created, each and every PCB in the world is designed using computer-aided design (CAD) software. This allows boards to be tested, as well as letting designers see that each of the tracers is connected properly as well as design and review the schematics of each board before physical development.

Conclusion

With the rate the world’s going, it’d be no surprise to see these agile and incredibly fast technologies power more electronics at an even smaller size. Anything is on the horizon with this tech, as scientists researchers tested biodegradable PCB boards in 2014.

If you are interested in even more technology-related articles and information from us here at Bit Rebels then we have a lot to choose from.

COMMENTS