A CNC machine is a machine that combines many distinct computer operations to make a relatively close shape by selectively removing raw material in controlled amounts. The CNC machine is divided into two parts: CAD, which deals with the design, and CAM, which deals with manufacture.

IMAGE: UNSPLASH

Parts Of A CNC machine

CNC machining parts include the following:

Bed

On CNC machines, they support the full weight of the machine, implying that all other components are positioned on them. Because the tool turret passes over the CNC lathe bed, the CNC lathe bed is made of hardened materials such as cast iron.

Headstock

Because the workpieces are fixed to it to complete an operation, the headstock is one of the most important components of CNC machines. The CNC lathe machine’s headstock also has motors that assist in driving the main spindle.

Tailstock

This CNC machine’s lathe is utilized to grip the workpiece better when performing operations like noodling, threading, and turning. Support is provided on the workpiece’s end surfaces.

Tailstock Quill

The tailstock quill aids in the centralization of workpieces between the headstock and tailstock.

Chuck

The chuck is situated on the main axle, giving the tool plenty of room to work.

Footswitch Or Panel

The pedal is used to open and shut the chuck while attempting to hold the component, such as with the tailstock quill, which is moved forward and reversed.

The Machine Control Unit (MCU)

This is the brain of the CNC machine. The MCU is in charge of all CNC machine control functions. Among the numerous responsibilities of the MCU are:

- It decodes the commands that are sent to it.

- The coded command is deciphered, where motion commands are generated using linear, spherical, and spiral approximations.

- The axis speed order is fed to the amplifier circuit, which drives the spindle mechanism.

- It receives position and speed feedback data for each drive axis.

Control Panel

Control panels are also crucial components of CNC machines since they are used to set or feed programs for operations on workpieces.

Tool Turret

A tool turret is an indexing tool holder for lathes, transfer machines, and other tools. They differ in shape and the number of tools installed on them. Typically, the complete tool turret is moved lengthwise to provide a feed for the tools, rotating along a vertical axis to bring each tool into the correct place during the turning cycle.

Display Unit

A monitor displays CNC machine programs, commands, and other useful data.

Driving System

The CNC machine’s driving system comprises an amplifier circuit, drive motors, and ball lead screws. The signals of each axis are fed into the amplifier circuit by the MCU.

The control signals are then amplified to operate the driving motors. Actuated drive motors revolve the ball lead screw to position the machine table.

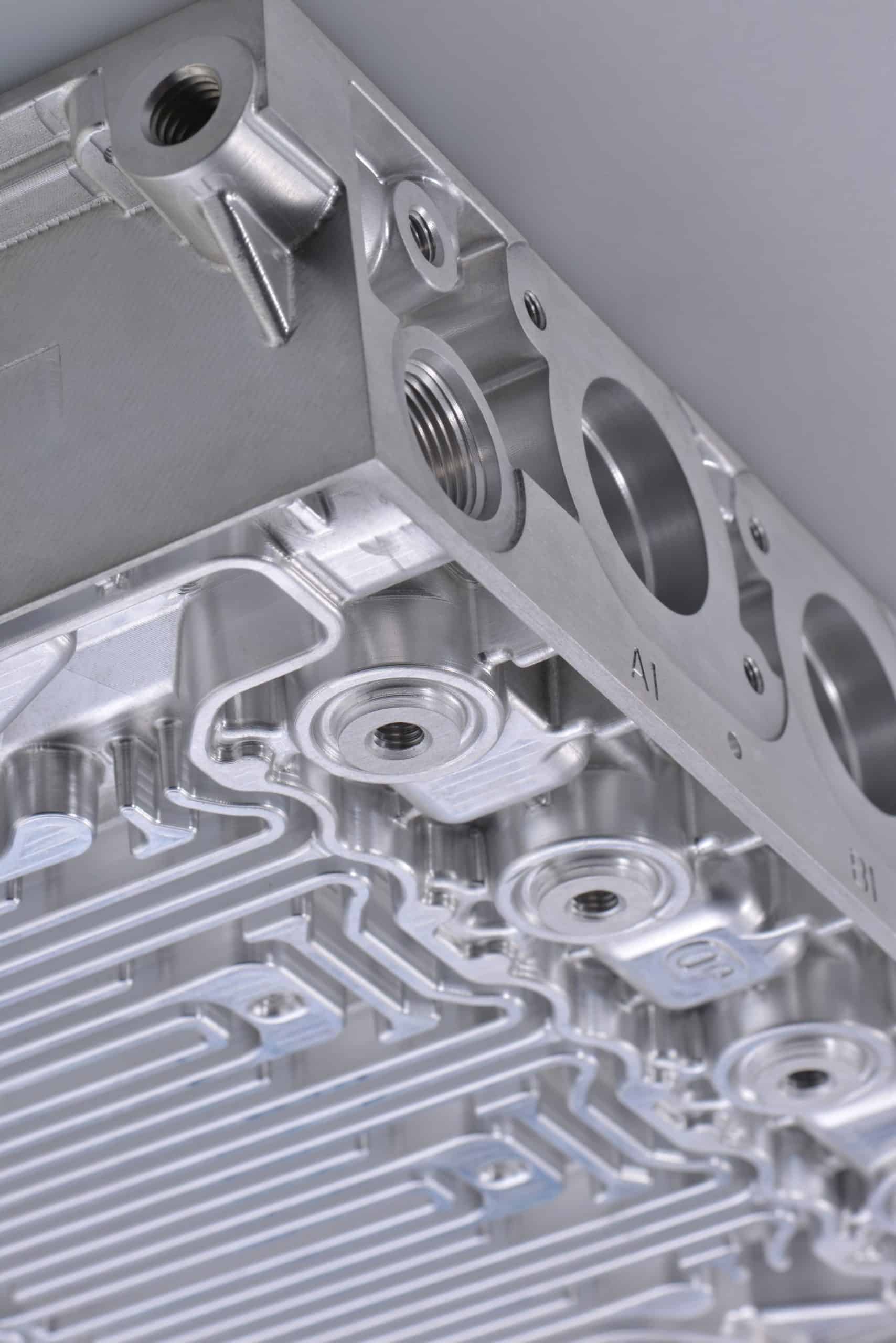

CNC Machining In Aluminium

Because of its outstanding machinability and ductility and superior strength-to-weight ratio, high thermal and electrical conductivity, low density, and natural corrosion resistance, aluminium is the most often manufactured material.

As a result, it is the preferred material for the vast majority of the manufacturing sector, and all you need to do is obtain a CNC Aluminium quote.

Conclusion

A CNC machine’s primary application is to remove metal faster than traditional equipment. The software-controlled parts seen above simplify traditional machining methods, making the task easier and requiring less human touch while eliminating worker neglect.

IMAGE: UNSPLASH

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS