In situ thermal remediation or heat treatment methods are widely used these days to mobilize or move harmful chemicals in groundwater and soil using heat. Under the impact of heat, the harmful chemicals travel towards collection wells through soil and groundwater.

The collected chemicals are then sent to the ground surface and treated with the help of different treatment techniques. During the heating process, however, some chemicals are also destroyed underground. This type of heat treatment is referred to as “in situ” because it applies heat directly to the contaminated underground area.

This method is particularly useful for the treatment of chemicals that are not readily soluble in groundwater. Known as non-aqueous phase liquids or NAPLs, these chemicals are a significant cause of groundwater contamination. Petroleum and creosote are two examples of NAPLs. Let us find out some important facts related to in situ heat treatment techniques.

IMAGE: PEXELS

How Does It Work?

In situ thermal treatment techniques function by heating up the contaminated soil and groundwater to very high temperatures. At these temperatures, the chemicals and water get vaporized and can move freely through the soil. Heat is generated by in situ methods in three different ways.

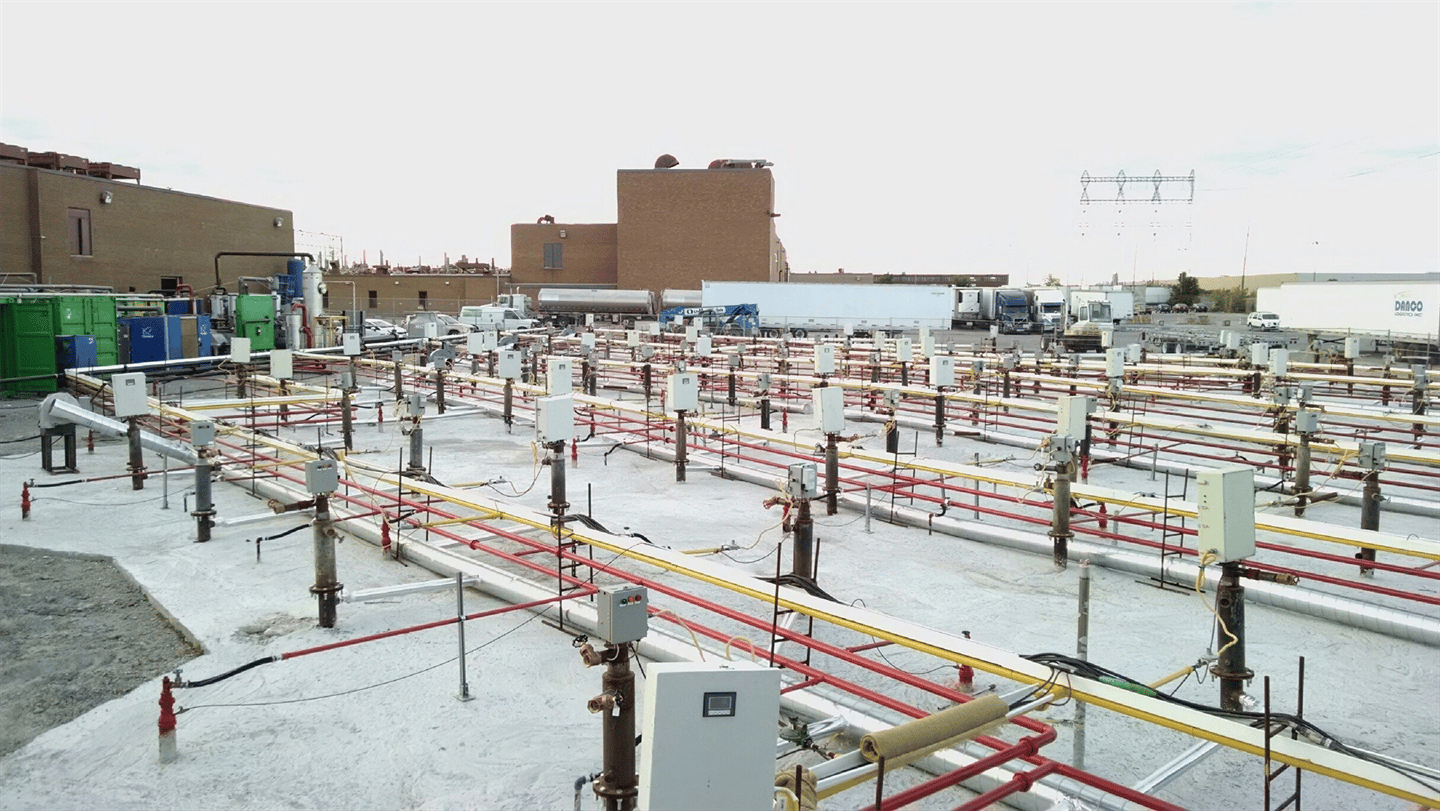

- Electrical resistance heating (ERH) is a method of delivering electrical current underground between the installed electrodes. As the current moves, it encounters resistance from the soil and heat is generated. This heat converts groundwater into steam and vaporizes the contaminants.

- Steam enhanced extraction (SEE) method involves drilling wells in the contaminated area and injecting steam beneath the ground by pumping through the wells. The area gets heated up by steam injection, resulting in evaporation and mobilization of the contaminants.

- Thermal conduction heating (TCH) is another in situ heat treatment method where heaters are placed underground within steel pipes for the application of heat. Some of the chemical pollutants present in the soil can be destroyed completely by the extreme heat generated by thermal conduction heating.

How Long Does It Take?

Including cleaning up the site, the completion of an in situ thermal treatment project may require a few months to a few years. Several factors determine the actual clean up time. It may take longer in certain circumstances such as

- Treatment of high contaminant concentration

- The contaminated area is deep or large.

- Presence of different soil types, resulting in uneven heating of the ground.

- If the soil is rich in organic matter, the chemicals don’t evaporate easily as they tend to stick to the soil.

How Safe Are These Methods?

If properly operated, situ thermal treatment techniques pose no threat whatsoever to the community of site workers. As an example, while using the electrical resistance heating method, common electrical grounding techniques are utilized to make sure that the electrical current is not able to travel beyond the treatment area. In order to keep the steam and heat underground, the treatment areas are covered by impermeable surface covers. This also minimizes the likelihood of releasing harmful vapors into the air.

Why Use These Methods?

In situ thermal treatment techniques are used extensively because they can speed the cleanup process for many different types of chemical contaminants. Also, these are amongst only a few of the in-site methods for cleaning up non-aqueous phase liquids.

Thermal treatment is also the only viable alternative for clayey or silty soil where other cleanup methods do not provide a satisfactory outcome. Another advantage of in situ thermal remediation is that this method can eliminate contaminations beneath buildings as well as deep underground. These treatments can be extremely expensive and challenging, using other cleanup methods.

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS