Product development is the first stage of every product’s lifecycle. It involves several different steps to transform a product idea into marketable components. A product’s lifecycle begins with the idea. This is the concept of how you wish the product should look. However, it is not enough to have an idea of what your component’s design should look like. Carrying out some form of prototyping is one of the essential components of the design thinking process.

The rapid prototyping services incorporate technical specifications, pricing strategy, product positioning, and many more. In every product development process, you need to consider the demand for the product, its producibility, how it will reach the customer, and ultimately how it will satisfy the customer. Rapid prototyping is one crucial process in every product development.

What Is Rapid Prototyping, And Why Is It Important?

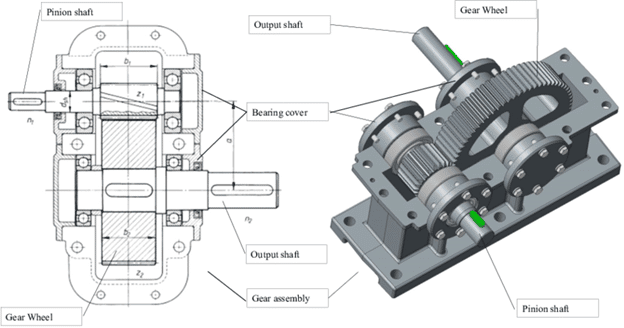

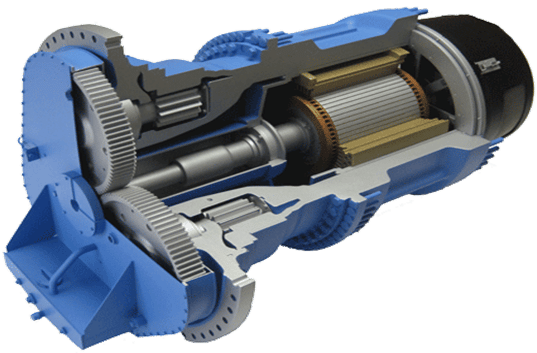

Rapid prototyping is a robust strategy used in the product development process. It is held to create 3-dimensional low-volume parts for testing and optimization of their characteristics. Prototyping offers you the opportunity to bring that idea to life. It involves the production of early, cheaper, and scaled-down versions of components.

If you’re looking to validate a hypothesis on how a product solves a problem, then rapid prototyping is the way to go. This helps to test the use of the current design and investigate what users feel about the product. The results obtained from the tests help to redefine the problems in the earlier design phases effectively.

Therefore, there is a more detailed understanding of the design for a better development process. The advantages of rapid manufacturing cannot be overemphasized, ensuring the following:

- Better Comprehension of the Design Intent

- Early Focused Feedback for Better Collective Design Decision

- Evaluation of Technical Feasibility

- Risk Reduction and Low-Cost Iteration

- Identification of Unnecessary Elements and Proper Streamlining of the Design Development Process

- Proper Validation Before Final Development

- Clear Presentation of Ideas to Customers

What Makes A Great Rapid Prototype?

A rapid prototyping process must identify what you want to test. Are you trying to validate a product idea? Or does it involve testing the design’s usability? It is essential to define your goal from the start of the process.

Building a great prototype involves some best practices to get the best out of the component. Rapid prototyping must be worked towards getting the product to market as quickly as possible. You should not spend too much time on a prototype; your ideas need to get out there for people to test as soon as possible.

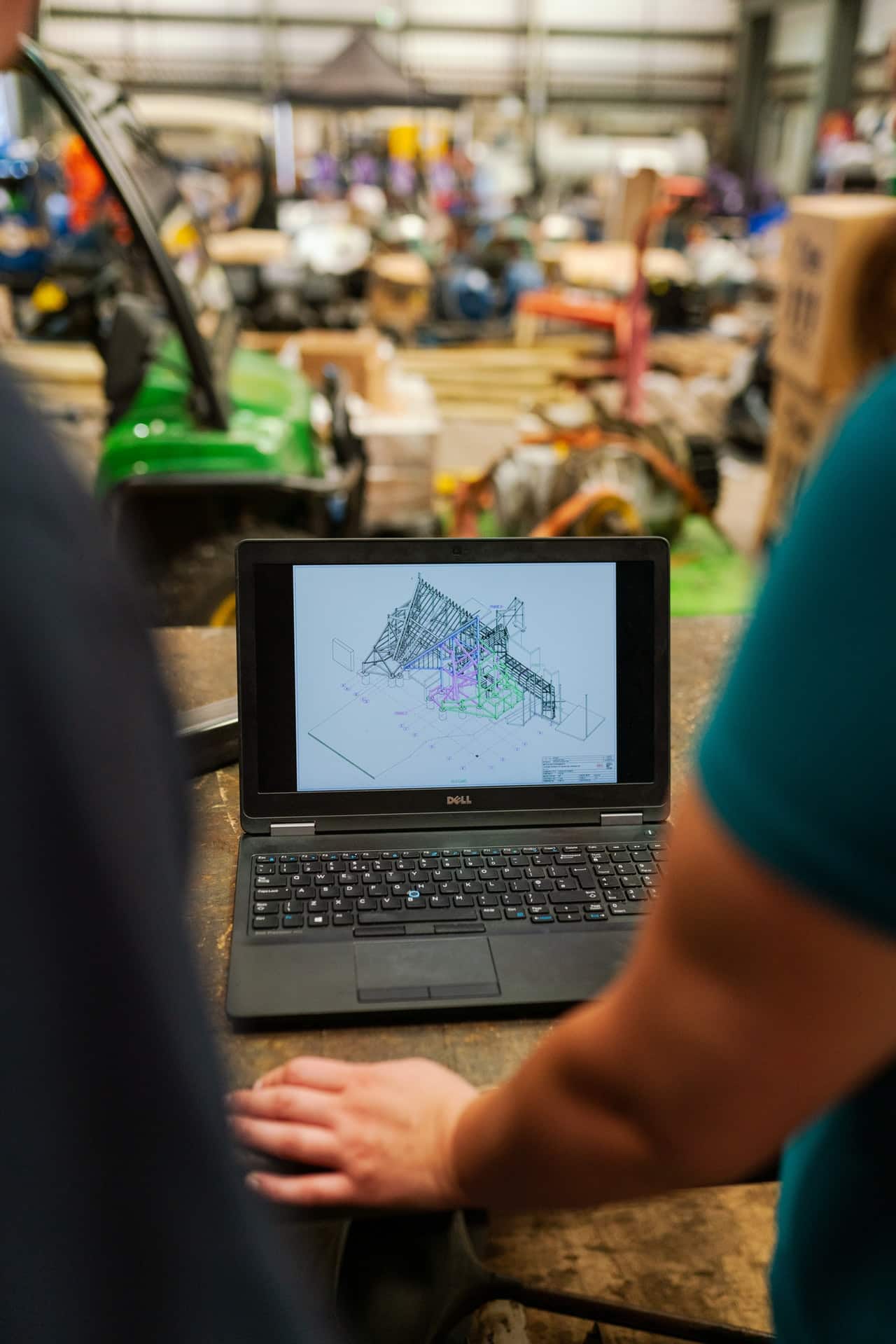

The process should also be helpful to every member of the production team. It must carry along product designers, engineers, manufacturers, managers, and marketers alike. This will help you yield valuable insights on the product and allow you to make the best product development decisions.

RapidDirect Rapid Prototyping Services

With specialized digital manufacturing techniques, RapidDirect is ready to bring your ideas to life. The experienced experts in rapid prototyping ensure efficient and quick manufacture of parts. The iterative approach also keeps the cost low, making it possible to produce inexpensive small series products.

There are prototypes available for various applications and purposes. With an advanced platform and problem-solving capacity, the creative possibilities and solutions are endless. The following rapid prototyping services makes RapidDirect stand out.

CNC Machining Services

RapidDirect is the ideal choice for your precision CNC machining services. With hundreds of quality materials and premium surface finishes available, you can be sure of the best services. These materials are combined effectively with experience and expertise to bring out the best results.

Sheet Metal Fabrication Services

RapidDirect offers top-notch custom sheet metal manufacturing and engineering services. You will get robust sheet metal solutions through optimum manufacturing techniques, materials, and surface finish options. The prototyping capacity is perfect for both prototyping and high-volume production.

Injection Molding Services

The injection molding services offered include a wide range of plastic manufacturing processes. There is also an extensive array of materials and finishes to meet your needs. The manufacturing capability is flexible, providing quotations within minutes. Also, The process included DfM feedback, production update, and certifications.

3D Printing Services

RapidDirect provides top-notch additive manufacturing for functional prototypes. There are several materials available, including various post-processing options. With an abundance of resources, cost-effectiveness will not be an issue. The quality of the end product is never compromised despite the short lead time.

Tech-Driven Automated DfM Feedback For Your Product Design

A rapid prototyping process should be easy and quick. This is why RapidDirect has incorporated the revolutionary tech-driven DfM feedback tool into the product development process. Once you upload your design file for an instant CNC quote, this robust software analyzes your file for manufacturability.

Rapid prototyping costs increase when the object involved is complex. The DfM tool reviews your design and points out features that may cause unnecessary expenses. It flags features like deep radius or hole, internal corner, thin wall, and narrow areas, and more. The digital inspection and small changes involve ensuring more cost-effective prototyping.

Get An Instant Quote For Your Rapid Prototype

Getting quotations for your design parts has become a lot more straightforward, thanks to RapidDirect’s instant quoting platform. All you need to do is upload your CAD file on the software, and you get an instant CNC quote. This instant quoting system boosts efficiency, shortens turnaround times, and saves cost.

You can easily order your prototypes and low-volume parts at competitive costs. This robust platform ensures the correct specification of requirements from the materials to the surface finish. It also provides an online DfM feedback analysis for CNC machining services. This ensures better product designs, faster lead times, and high-quality products.

There is no more stressful exchange of files and countless email chains. You can be sure of a faster manufacturing process with RapidDirect’s instant quote. This digital environment ensures that you can focus on getting the product to market within a short period.

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS