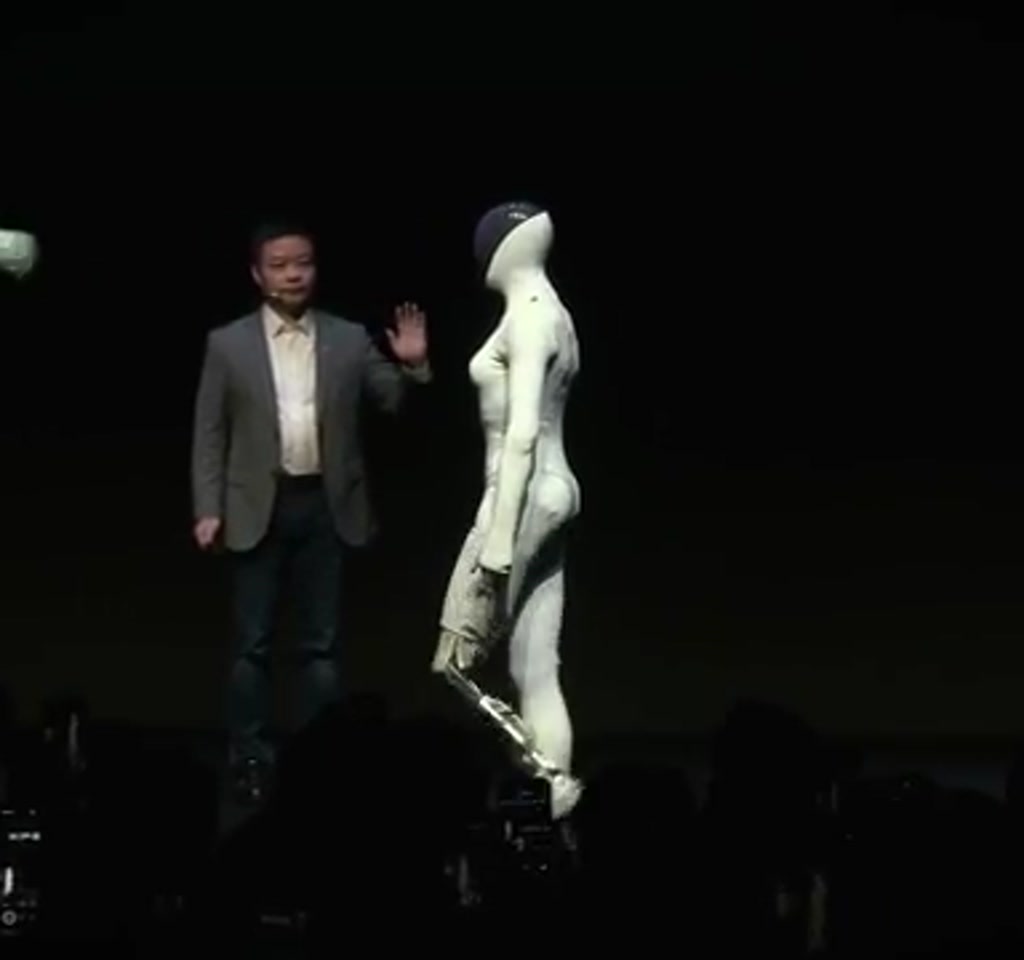

XPENG Robotics has a simple-sounding ambition: create the most human-like robot possible. That sentence reads as a promise, but the company’s recent presentation of IRON shows the work required to turn promise into practice. The meaningful advance is not a single new actuator or softer skin. It is a body logic that coordinates anatomy, materials, and machine learning so the whole system behaves like a single instrument.

The primary insight here is this, stated plainly: what makes a robot feel human is less about copying the look of a limb and more about designing an integrated backbone for behavior. XPENG Robotics calls that approach a general-purpose humanoid design framework. It governs proportions, degrees of freedom, sensor layout, materials, and the learning methods that drive motion. That framework is what keeps a platform balanced, expressive and coherent when scaled to different sizes or use cases.

Most readers will assume lifelike movement is solved by high-torque motors or high-resolution sensors. That is a part of the answer, but the real work sits behind the scenes in three connected places: the mechanical strategy of the waist and spine, the muscle-like lattice that changes interaction dynamics, and the control stack rebuilt to learn with those materials in the loop. XPENG’s account makes clear that each of those elements must be engineered together, not one at a time.

What becomes obvious when you look closer is that IRON is an argument about tradeoffs. Add softness and the physics become harder. Add degrees of freedom and the learning problem grows. XPENG’s contribution is procedural: identify which mechanical choices give the largest perceptual return and then invest in the data and algorithms needed to make those choices predictable and repeatable.

The Body Logic Behind Human-Like Motion

XPENG Robotics frames IRON around a body logic—a design philosophy that treats the robot as an embodied system rather than a collection of modules. That philosophy shows up in three concrete design decisions: compact skeleton geometry, a muscle-like lattice for compliant motion, and an outer skin tuned for tactile familiarity. Each layer is optimized not merely for its own performance but for how it changes the dynamics the controller must handle.

A Framework Not Just A Look

The design framework is explicitly general-purpose. XPENG positions it as a way to keep behavior coherent across different sizes and roles. In other words, the same body logic that produces a natural shrug in a compact unit should scale to larger configurations used in different environments. The point is coherence: people recognize humanness through motion patterns and proportions as much as through facial features.

Layered Construction: Skeleton, Muscles, Skin

IRON is described as built layer by layer. The compact skeleton defines primary kinematics. The lattice material functions as muscle and soft tissue, introducing compliance and more biologically familiar force transmission. Finally the skin softens interactions. This layering is not purely cosmetic; each layer shifts the control problem in predictable ways and therefore influences where the research effort must be concentrated.

Why The Waist Becomes The Secret

One of the more surprising editorial takeaways is how central the waist proved to be. XPENG’s team reports that the degrees of freedom at the waist are disproportionately important for natural-looking motion. Instead of settling for simple rotational joints there was deliberate engineering to mimic a human spine, providing twist and flex that change whole body posture.

That choice raises a familiar tension in robotics: mechanical expressivity can improve believability, but each added degree of freedom increases control complexity. XPENG’s experiments showed diminishing returns once the control burden outpaced perceptual gains, so the waist design is a calibrated compromise between motion richness and predictable behavior.

The Muscle Lattice And Simulation Hurdles

XPENG’s lattice material is an explicit attempt to close the tactile gap between machine and human. But that decision created a hard technical problem. The lattice has structural and damping properties that are difficult to model with standard simulation methods, and that unpredictability breaks the feedback loop that learning algorithms depend on.

System Identification At Scale

To address this, XPENG collected large dynamic datasets and developed targeted system identification routines for the lattice. Realistic soft materials push data needs up by at least an order of magnitude compared with rigid prototypes; the extra measurement and calibration stages routinely add days to weeks to timelines and increase compute usage when used in learning loops.

Turning The Lattice Into Predictable Behavior

Combining calibrated models with structural optimization made the lattice tractable in simulation. That coordination of hardware, simulation, and control enabled faster iteration and more stable controllers. The practical lesson is clear: when materials fall outside standard models, engineering response favors data, tighter calibration, and design loops that assume imperfect priors.

Rebuilding Learning For A Soft Body

Controlling IRON demanded more than incremental algorithm tuning. XPENG reports that reinforcement learning methods were redesigned to be efficient and robust for the platform’s particular dynamics. When the body changes, the control software must be rethought, not merely retuned; this is a structural engineering observation with operational consequences.

Training Time And Compute Tradeoffs

Training motion controllers at this level commonly requires extended computation. What used to be minutes of tuning can become days or weeks of continuous training runs, depending on the problem. That shift defines whether a design is practical for rapid iteration or constrained to long refinement cycles and higher development budgets.

Robustness To Material And Appearance Changes

XPENG highlights robustness: controllers retained smooth, human-like motion even when muscle structures or skin materials changed. That robustness comes from intentionally widening the training distribution and choosing objectives that favor graceful motion over raw peak performance, which increases data and compute needs but reduces brittle failures in varied conditions.

IRON Versus Conventional Humanoids

Comparing IRON to more conventional humanoid approaches clarifies decision factors: IRON prioritizes compliant interaction and perceptual believability, whereas many conventional designs favor rigid repeatability and simpler control. The choice between them depends on application needs—expressive presence or low-cost, high-reliability operation.

Expressivity And Tactile Interaction

IRON’s spine-inspired waist and muscle lattice boost expressivity and safe physical interaction, making gestures and hugs feel more natural. Conventional humanoids with rigid torsos can be more predictable and cheaper to simulate, but they lack the same tactile nuance and the humanlike posture shifts that viewers quickly recognize.

Development Cost And Time

Soft, calibrated designs demand heavier investment in data collection, simulation fidelity, and training compute. Conventional rigid designs typically move faster from prototype to repeatable behavior because their physics are easier to model. That difference often dictates whether a project is feasible within a given timeline and budget.

Tradeoffs And Constraints That Define Usefulness

The IRON story is not a victory lap. It is a compact demonstration of how practical robotics emerges from balancing tradeoffs. Two constraints stand out and shape the platform’s real-world usefulness: simulation and data cost, and degrees of freedom versus control complexity.

- Simulation And Data Cost: Making the lattice predictable required substantial dynamic data collection and model calibration. This typically shifts development timelines by days to weeks and increases compute usage into multi-day training runs rather than single-session tuning.

- Degrees Of Freedom Versus Control Complexity: Adding waist and torso DoF improves expressivity but increases control burden faster than usefulness. When DoF grow into double digits the training and validation burden tends to scale at least linearly and often superlinearly.

Other practical constraints include power delivery and continuous operation. Actuation and sensing for compliant motion increase power draw and thermal load, which will influence deployment models and may push some use cases toward tethered setups or purpose-built power systems rather than fully autonomous battery operation.

What The Design Choices Mean For Adoption

XPENG Robotics is advancing a coherent, repeatable approach to human likeness rather than presenting a single product stunt. That coherence matters because it reduces the need to invent new algorithms and recalibration for every prototype. The real adoption question is whether teams will accept the data and compute budgets this body logic requires.

There will always be deployment boundaries. The approach holds when teams invest in data collection and in long training cycles, and when use cases tolerate higher hardware and development costs. For contexts where simplicity and low cost matter more than lifelike motion, alternatives that favor rigidity and fewer DoF remain preferable.

Who This Is For And Who This Is Not For

Who This Is For: Research labs, companies building collaborative assistants, and teams that prioritize natural interaction over minimal cost. These groups can justify larger data budgets and longer iteration cycles to achieve tactile, humanlike behavior.

Who This Is Not For: Applications where low cost, minimal maintenance, and maximal predictability are essential. If the priority is rapid deployment on a tight budget, rigid-body humanoids or simpler mobile manipulators will likely be a better fit.

Cultural And Practical Implications

Robots that move like humans change the social frame for interaction. People interpret posture and gesture instinctively, so when machines adopt those cues they become easier to collaborate with. That is the promise XPENG points toward: machines that mirror human rhythms, not alien tools. The unpredictable part is cultural: how societies decide to use those machines will shape expectations faster than individual technology milestones.

From a practical standpoint, material wear and maintenance cycles will surface as usage scales. Materials engineered for touch will face wear after repeated use cycles measured in hundreds or low thousands, and that will require design attention to service economics and supply chains as much as to controls.

FAQ

What Is XPENG Robotics IRON?

IRON is XPENG Robotics’ humanoid platform that emphasizes human-like motion using a spine-inspired waist, a compliant muscle lattice, and an integrated control stack calibrated to those materials.

How Does The Spine-Inspired Waist Help Motion?

The waist provides twist and flex that change whole body posture, increasing kinematic expressivity. XPENG found these degrees of freedom disproportionately influence perceived humanness while requiring careful control tradeoffs.

What Is The Muscle Lattice And Why Is It Hard To Simulate?

The lattice is a compliant structural layer that mimics soft tissue. Its damping and nonlinear properties are difficult to model with standard simulation, which necessitated large-scale system identification and calibration.

Does Using Soft Materials Increase Development Time?

Yes. Realistic soft materials push data needs and simulation fidelity up by at least an order of magnitude compared with rigid prototypes, commonly adding days to weeks to development and increasing compute for training loops.

Is IRON Ready For Commercial Deployment?

IRON demonstrates a repeatable design practice but is not presented as a turnkey commercial product. Adoption depends on whether organizations accept the increased data, compute, and material costs required for lifelike motion.

How Does IRON Compare To Conventional Humanoids?

IRON prioritizes tactile interaction and expressive motion through compliant elements and a flexible waist. Conventional humanoids often favor rigid structures for predictability, lower simulation cost, and faster iteration.

Can The Same Body Logic Scale To Multiple Units?

XPENG proposes a general-purpose body logic intended to scale. The transcript suggests scaling is plausible but contingent on reusing calibrated simulation and learning recipes across units; practical economics and service considerations remain open questions.

What Should Teams Consider Before Choosing This Approach?

Teams should weigh data collection budgets, training compute, maintenance and power requirements, and whether the use case benefits from lifelike motion enough to justify those costs.

COMMENTS