Most organizations have embraced 3D printing in recent years, while others have substituted it with subtractive manufacturing. A study has indicated that over 80% of manufacturers have embraced this technology. Another 60% of these manufacturers believe that this technology will increase product development.

A custom 3d printing service has more advantages to an organization than you think, and below, we discuss a few.

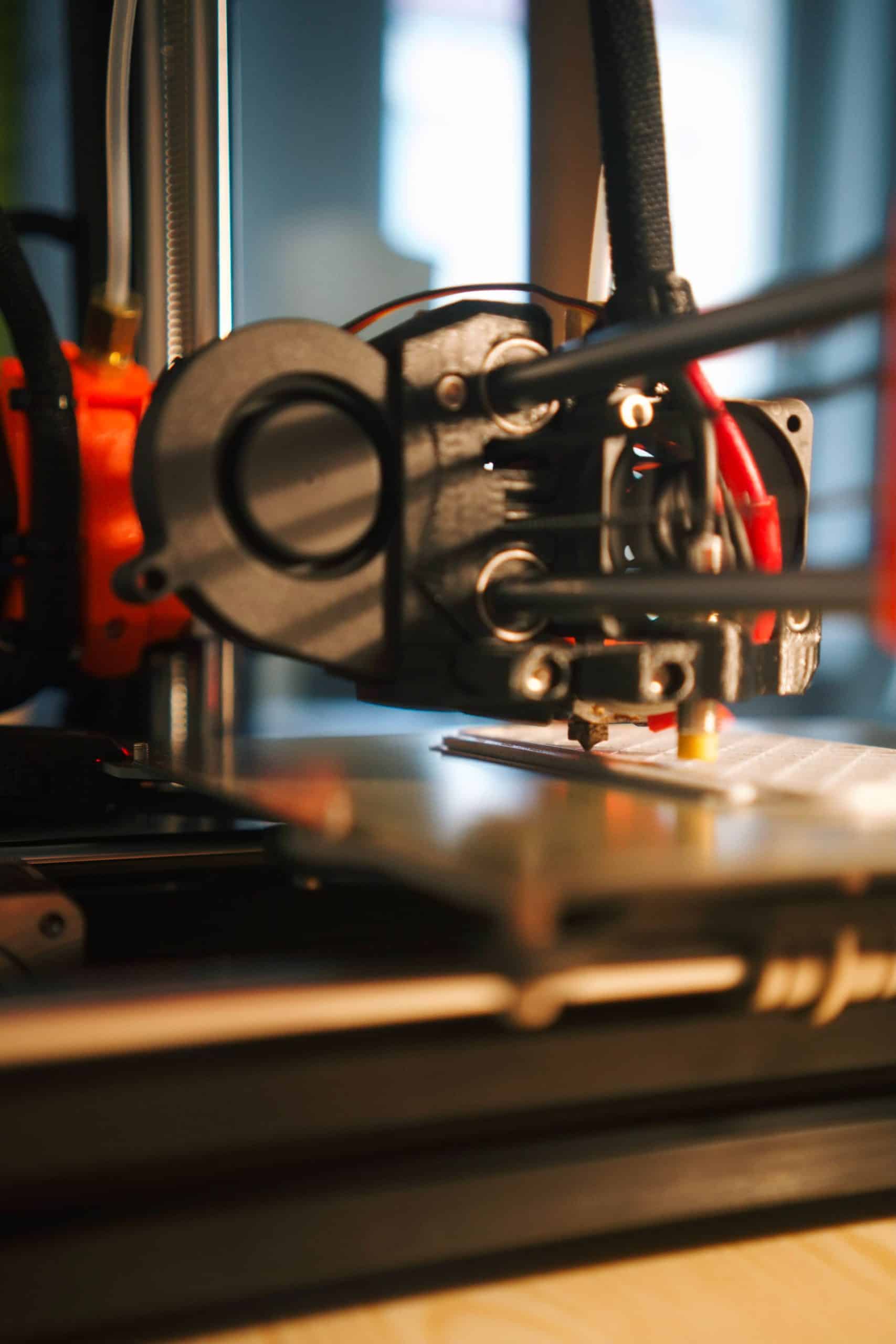

IMAGE: UNSPLASH

1. Faster Production

3D printing is more rapid than subtractive production and injection molds. This printing technique tests designs and ideas faster than other methods. Better prototype production and faster plans mean you will find the market faster than your rivals.

It takes a few hours to design using this technique, with the most complex tasks lasting hours. Testing designs and ideas also takes a few days.

2. Improved Quality

Traditional manufacturing modes create poor designs, meaning poor prototype quality. Subtractive and injection methods reduce a product’s quality due to the excess waste. 3D printing lets you assemble your project step-by-step, guaranteeing you a better object quality.

3. It Is Easily Accessible

3D printing has existed for many years but became popular around 2010. 3D printing interests have exploded recently, making it easy for consumers to access hardware and software.

3D printing technology is also easy to learn, and you can incorporate it into your production cycle in days.

4. Creates Tangible Designs

Seeing a product virtually cannot be compared to a prototype feel. This printing technology offers this benefit, and it is possible to feel the touch of a specific prototype. It is also possible to modify a CAD file if a problem is found, and you can print the latest version in a few days.

5. It Has Creative Designs

Traditional techniques cannot create excellent copies of the same item. These conventional methods create dull designs that cannot be improved much. It is also challenging to make unique designs using these methods. Reach out to us for a CNC service at affordable rates.

3D printing gives you endless personalization that enables you to include personal touches per the client’s wish. With this printing, the only limitation you have is your imagination. It is used in the medical sector to make teeth crowns.

This will reduce a patient’s number of visits to the dentist.

6. It Boasts Endless Geometry And Shapes

Traditional methods depend on cutting technologies and molds to create specific shapes, making it hard to design complex geometrical shapes. 3D printing handles this challenge quickly and can handle complex tasks with the correct support material.

7. It Implements Raw Materials

Product designers must calculate their steps keenly when using a mold or subtractive manufacturing materials. Raw material blending is not supported in mass manufacturing since it is expensive.

Also, mixing physical and chemical elements is complex. However, with 3D printing, you can easily accommodate several raw materials like paper and glass.

Final Thoughts

3D printing has many advantages, explaining why it is available in almost all industries today. Some top benefits include lesser waste production and better product quality. Kindly reach out to us for more help.

IMAGE: UNSPLASH

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS