Engineers are continually weighing different options when it comes to design and prototyping. Knowing which machining process to choose, however, can be challenging at times. With so many industry options today, engineers have even more details to consider than in the past. Learn how to choose between 3D printing and CNC machining as engineers narrow down both the design and budget concerns for a project.

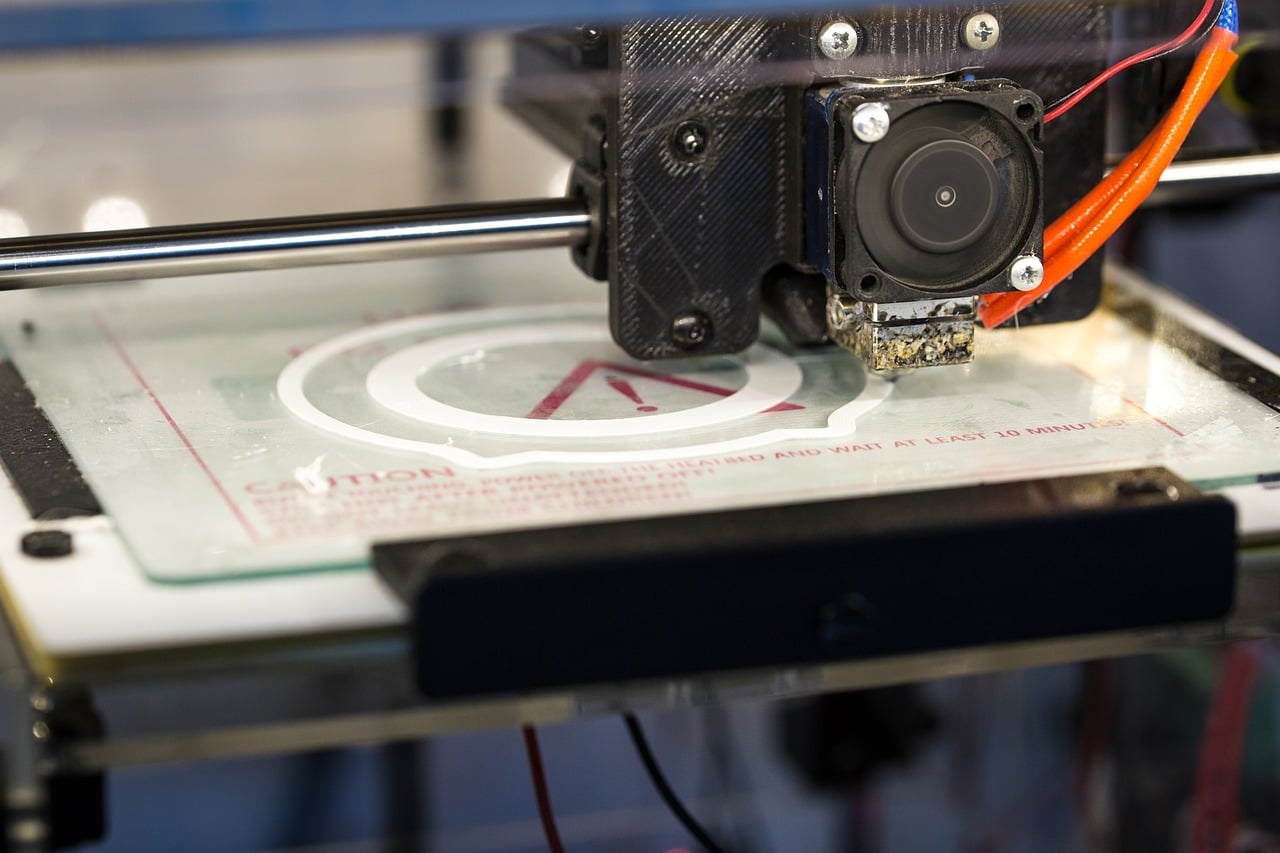

IMAGE: PIXABAY

Exploring The Processes

Because 3D printing is the latest craze, many engineers automatically pick out this process for their designs. The cost isn’t necessarily right for the project, however. Remember that subtractive prototyping or CNC machining is perfect for simple designs. There’s no need to go through the complexities found in a 3D program every time.

Engineers will find that CNC machining offers precision accuracy if a mechanical assembly is part of the design. In contrast, look to 3D printing when an item doesn’t have mechanical parts and requires some complex shapes. Engineers will spend less time on the prototyping session as a result of these choices.

Volume Considerations

A twist on the industry occurs when neither CNC nor 3D printing is viable options. Engineers may want thousands of parts made for a particular department. The cost can be astronomical with both additive and subtractive production.

Consider injection molding in these cases. Although this technology is standard, it remains a staple for prototyping and large-scale production. Always consider 3DP for more moderately sized projects. If engineers need between 50 and 100 items created, 3D options tend to win out over CNC or IM. Each project will dictate the right choice.

(Bild 2)

Skipping The Local Shop

Choosing an online service, such as 3D Hubs, for prototyping and printing needs is a smart alternative to local shops. Experienced engineers are accustomed to waiting for weeks if not months, when local services are backed up.

There’s no line for online services. Upload a design and see it made in record time. These 3D printing services include CNC prototyping, 3D printing, and injection molding. If an engineer is unsure about which option works for his or her budget, contacting the service should always be a go-to choice. Skipping the local shop will always save time and money in the long run.

A Double-Checking Option

Most 3D printing services simply take a design, make it, and allow the engineer to evaluate the final product for flaws. Mistakes are almost always part of the scenario. Working with 3D Hubs is a unique experience because each order comes automatically with Design for Manufacturing or DFM analysis. Before any products come out of the service, the system reviews the design. It detects any anomalies and notifies the engineer.

Alterations can be made well before any materials are laid out for the project. Removing any issues from the design makes the prototyping service that much more successful. Try 3D Hubs instant quotes today. Our team remains dedicated to the design and engineering world. An engineer’s passion is our fascination. Allow us to make that dream a tangible reality.

If you are interested in even more design-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS