If you’ve ever had an idea for a product but didn’t know how to bring it to market, you’re not alone. In fact, the process of taking an idea from concept to reality is notoriously difficult and often requires years of development and expensive tooling costs. But what if there was a way to rapidly prototype your ideas and bring them to market faster?

That’s where rapid prototyping comes in. Rapid prototyping and prototype manufacturing is a process by which products can be quickly created using 3D printing or other techniques. This allows businesses to rapidly test ideas and iterate on them quickly, without the need for expensive tooling or long lead times.

In this blog post, we’ll explore why rapid prototyping is the future of bringing your ideas to market. We’ll also look at some of the benefits and challenges associated with this technology.

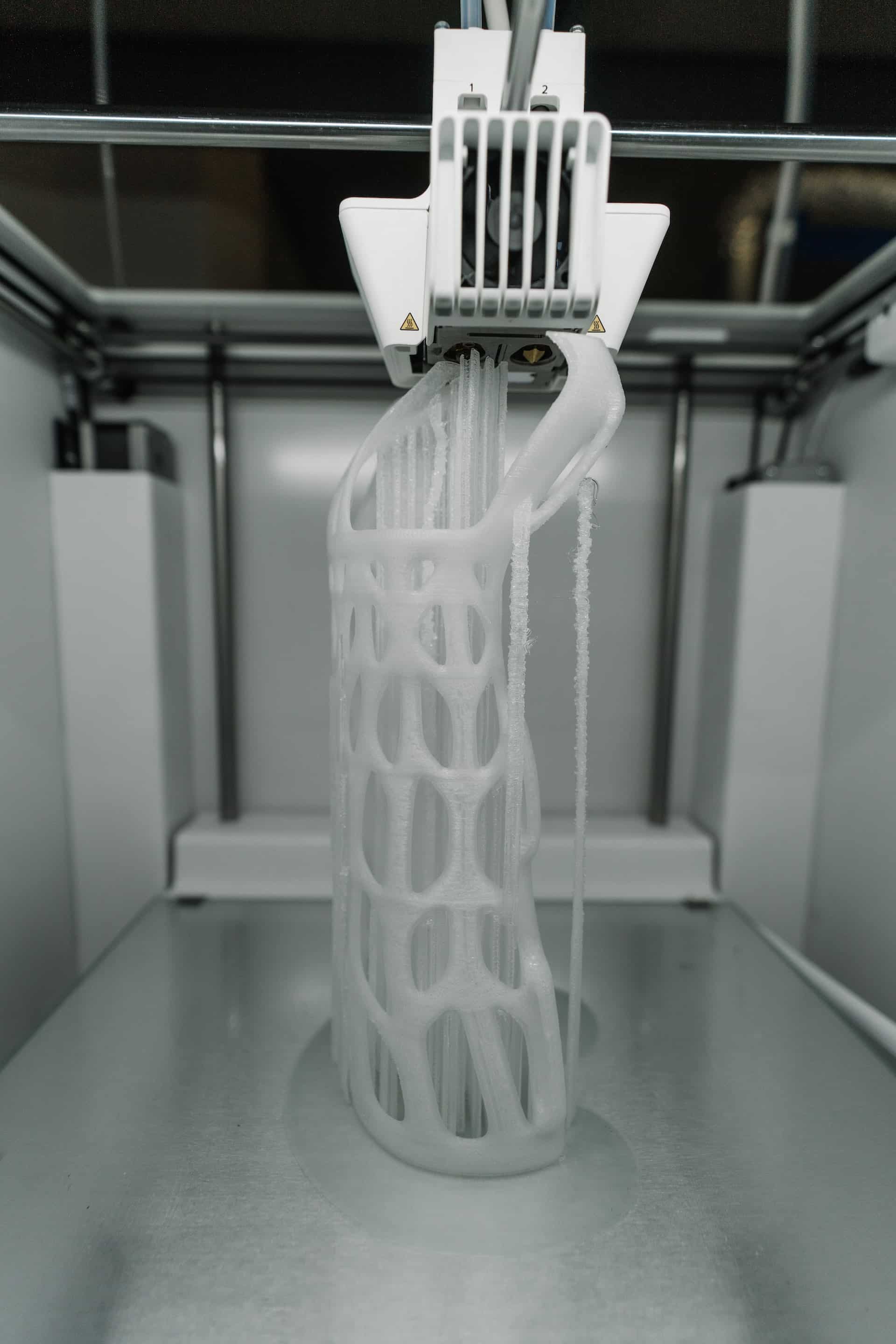

IMAGE: PEXELS

What Is Rapid Prototyping?

Rapid prototyping is the creation of a working model or prototype of a product using quick and easy methods. It allows businesses to bring their products to market faster and with less risk.

There are many different types of rapid prototyping technologies available, each with its own strengths and weaknesses. The most common rapid prototyping technologies are stereolithography (SLA), selective laser sintering (SLS), fused deposition modeling (FDM), laminated object manufacturing (LOM), CNC machining, vacuum casting, and sheet metal fabrication.

SLA is the oldest and most established of the rapid prototyping technologies. It uses a laser to draw a design onto a layer of photopolymer resin, which hardens when exposed to the laser light.

Advantages Of Rapid Prototyping

When it comes to bringing your ideas to market, rapid prototyping is the future. This is because there are so many advantages to using this method that it’s hard to ignore.

First and foremost, rapid prototyping is fast. This means that you can get your product to market much quicker than if you were to use traditional manufacturing methods. In addition, rapid prototyping is also more accurate. This means that you’re less likely to run into problems when your product goes to market.

Another advantage of rapid prototyping is that it allows you to test your product before it goes to market. This way, you can make sure that it works the way that you want it to and that there are no unforeseen issues.

Finally, rapid prototyping is also more cost effective than traditional methods. This means that you can save money while still getting your product out there quickly.

How Rapid Prototyping Can Help You Bring Your Ideas To Market Quickly

If you’re an entrepreneur or product development professional, chances are you’ve heard of rapid prototyping. Rapid prototyping is a process of quickly creating a physical model of a product or concept using 3D printing or other manufacturing techniques. It’s an iterative process that allows designers and engineers to test different approaches and refine their designs before going into full-scale production.

By being able to rapidly prototype your product, you can get feedback from potential customers early on in the development process. This feedback can be invaluable in helping you make decisions about what features to include, what materials to use, and how to best manufacture your product.

Rapid prototyping can also save you time and money by allowing you to test different design concepts before committing to a final design. By doing this, you can avoid costly mistakes that could delay your product’s launch or cause problems down the line. And because rapid prototyping is such a fast process, you can iterate on your design multiple times until you get it just right.

So if you’re looking for a way to bring your ideas to market quickly and efficiently, consider using a rapid prototyping service like X Rapid Technologies. It’s a powerful tool that can help you iterate on your designs, save time and money, and get valuable feedback from potential customers.

What Are The Various Services Available In Rapid Prototyping?

There are many different types of rapid prototyping services available, each with its own advantages and disadvantages.

3D Printing

3D printing is one of the most popular rapid prototyping services. It is fast, relatively inexpensive, and can be used to create complex shapes and designs. However, 3D printing is limited by the materials that can be used and the accuracy of the final product.

CNC Machining

CNC machining is another popular rapid prototyping service. It is more accurate than 3D printing and can be used to create products from a variety of materials. However, CNC machining is slower and more expensive than 3D printing.

Laser Cutting

Laser cutting is another rapid prototyping service that offers high accuracy and precision. It can be used to create products from a variety of materials, including metals, plastics, and glass. However, laser cutting is slower than producing a CNC machining prototype and more expensive than 3D printing.

Stereolithography

Stereolithography (SLA) is a rapid prototyping technology that uses ultraviolet (UV) light to cure photopolymer resins into solid objects. SLA offers high accuracy and resolution, making it ideal for creating prototypes with intricate details. However, SLA is slower than CNC machining and more expensive than 3D printing.

Vacuum Casting

Vacuum casting is a rapid prototyping technology that creates prototypes from silicone molds. Vacuum casting offers high accuracy and resolution, making it ideal for creating prototypes with intricate details. However, vacuum casting is slower than CNC machining and more expensive than 3D printing.

Reaction Injection Molding

Reaction injection molding (RIM) is a rapid prototyping technology that creates prototypes from two-part liquid resins. RIM offers high accuracy and resolution, making it ideal for creating prototypes with intricate details. However, RIM is slower than CNC machining and more expensive than 3D printing.

Custom Sheet Metal Prototype

The method for sheet metal prototype fabrication can vary, but there are four general processes that are used, such as sheet metal forming, sheet metal bending, sheet metal cutting, and sheet metal stamping.

What Are Some Of The Challenges Associated With Rapid Prototyping?

One of the challenges associated with rapid prototyping is the potential for errors. Because prototypes are usually created quickly, there is less time to catch and correct mistakes. This can lead to problems later on if the errors are not caught and corrected early enough in the design process.

Another challenge with rapid prototyping is that it can be expensive. The cost of materials and equipment can add up quickly, especially if you need to create multiple prototypes. In some cases, it may be more cost-effective to outsource the rapid prototyping process to a professional service if you don’t find the right service to use, like X Rapid Technologies.

Finally, rapid prototyping can be challenging because it requires a high level of coordination between different team members. Each team member must be aware of what the others are doing in order to avoid duplication of effort or confusion.

X Rapid Technologies – Leading The Path Of The Prototyping Industry

X Rapid Technologies is a revered rapid prototype service provider that’s been successfully offering its wide range of services for well over a decade now. Located in Shenzhen city, China’s Silicon Valley, the company has helped thousands of businesses and individuals get their products to market.

The company prides itself in being one of China’s leading providers of quick prototyping solutions and offers an impressive array of services such as CNC machining, SLA/SLS 3D printing, vacuum casting, sheet metal fabrication, plastic injection molding, and many more.

Anyone looking for high-quality rapid prototype services can count on X Rapid Technologies to deliver. The company makes use of the latest state-of-the-art machines and equipment available today to produce prototypes that are fit for testing before mass production is initiated. It’s this commitment to perfection that has seen them gain such widespread popularity among clients all over the world.

X Rapid Technologies believes in providing its clients with nothing but the best and promises 100% customer satisfaction at all times. Over the years, it has established itself as one of the most reliable rapid prototyping service providers out there. This can be clearly seen from the many positive reviews that have been left by some of its most satisfied clients.

Why X Rapid Technologies?

The biggest advantage of working with this rapid prototype service provider is that it employs a team of highly skilled engineers who make use of the latest machines to produce prototypes at an extremely fast rate.

This allows clients to save significant amounts of money by opting for X Rapid Technologies instead of other companies in the industry, which might charge more and also take a lot longer to get the job done.

The quality provided by X Rapid Technologies is also consistently high, which is why so many businesses continue to opt for their services time and time again.

Conclusion

Rapid prototyping is a powerful tool that can help you bring your ideas to life quickly and efficiently. Whether you’re looking to create a new product or improve an existing one, rapid prototyping can help you get the job done faster and better than ever before.

If you’re not already using rapid prototyping in your business, now is the time to start. Our suggestion is to check out their case studies section and then reach out to X Rapid Technologies and see the future unfold in front of you.

IMAGE: UNSPLASH

If you are interested in even more design-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS