CNC machining advance and improve every year, meaning they become more complicated. The frequent updates make it hard to stay updated with the dos and don’ts of the design. You can decrease machine pricing while enhancing its function ability using certain adjustments.

Companies use automation software to estimate quotes and parts that need a redesign. This software detects unmanufacturable features. It also suggests parts that do not need change. The software helps to enhance the machine’s general design.

This article will discuss some top ways you can lower the CNC costs. It will help to contact an expert to get a CNC instant quote.

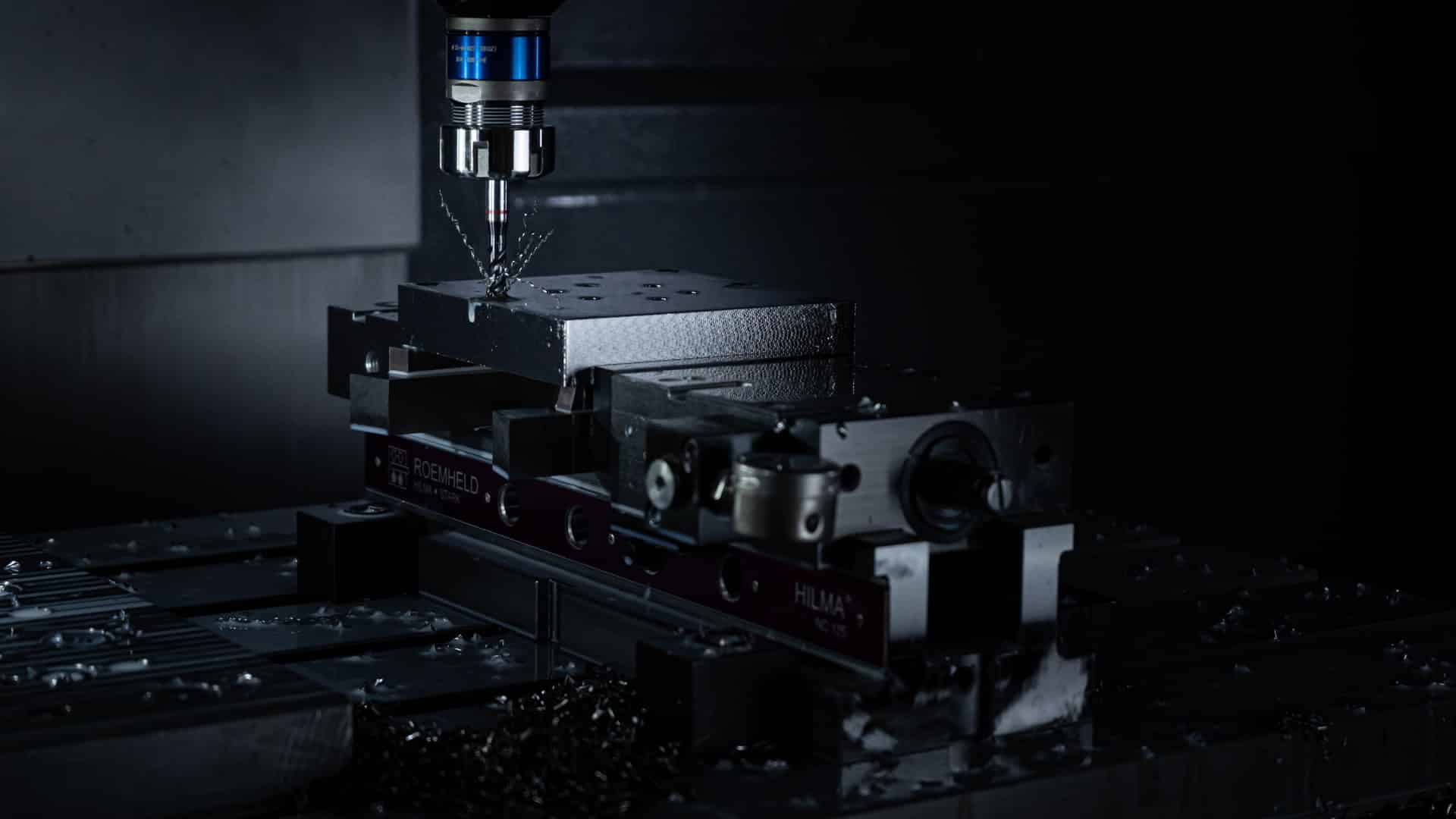

IMAGE: UNSPLASH

1. Ensure The Corner Pockets Are Relieved

It will help to consider your machine pocket’s corners to cut these costs. One most used design is sharp vertical walls. You can also use undercut shapes if the edges have sharp corners in place of lowering the radius. It is advisable to add undercuts at the cavity’s corner if it is rectangular.

Deep cavity procedures increase machining costs because you must remove many materials. This also takes a lot of time. Remember, CNC tools have a specific cutting length. Most function well when removing cavities whose depth is 3-4 times their diameter.

It is possible to cut deep cavities, but they are costly. This is because you need a machine called multi-axis CNC to get the job done. 3D printing services involve the process of making three dimensional objects using a computer.

2. Boost The Thickness Of Thin Walls

You will lower the machining time by increasing the thickness of the walls. It would help if you also considered thick sections unless weight is an issue. These sections are cheap and easy to use. It would help if you also had several passes at low cutting to prevent a fracture.

Thin features are more likely to absorb vibrations, meaning it is hard to match them. This feature also doubles machining time. Do the following things to lower the cost;

- Ensure the walls have a 1.5mm thickness for plastic parts

- Designs walls with a 0.8 thickness for metallic parts.

The least thickness you can use for metals is 0.5 and 1.0 for metals.

3. Limit Your Thread Length

It is advisable to limit your thread length to lower machining costs. You will increase these costs by using long threads, and this is because you need specific tools. Also, remember threads with a bigger diameter do not strengthen the connection.

You can do the following things to minimize costs;

- Create threads that have a length three times the diameter

- Add half-diameter threads at the bottom.

4. Use The Least Machine Setups Possible

It is advisable to use parts that you can machine in the least setups possible. Parts with blind holes on either side will have two-setup machining. This is because you must rotate it to access all sides.

You should reposition these parts manually for the most effect. A custom feature is also used for intricate geometries, and this increases the cost. Some complex geometries need a multi-axis system, and this increases the cost.

It would help if you considered splitting these parts into sections you can machine in one setup. This should also be applied to parts that have deep pockets. You can lower the cost using the following steps;

- Create parts you can machine in one setup

- Split the geometry into several parts you can assemble later.

5. Make Holes In The Typical Size

It will help to use standard sizes when making holes. It is possible to CNC machine these holes fast by the use of drill bits. You must machine the hole using a mill tool for non-standard sizes. All these processes increase the cost.

It is also advisable to limit the depth of your hole to five times its diameter. You can also design deep holes, but they will double the price. It would help to do the following things to lower the cost;

- Make holes with diameters of up to 11 mm

- Use convectional fractions when designing inches

- Make holes that have a length exceeding their diameter.

6. Use Tolerances Only When Needed

Tight tolerances increase the CNC cost since it doubles the machining time. It also needs frequent inspection. It is advisable to define tolerances sparingly to keep the costs down. The use of the standard tolerance will classify the parts of a specific tolerance. This occurs if it is not defined on the drawing.

It is hard to achieve tight tolerances on internal features. Defects might appear at the edges when intersecting cavities due to material deformation. Follow the below steps to lower machining cost;

- Use tighter tolerances when necessary.

- Define a datum when referring to all tolerance dimensions.

Final Thoughts

CNC machining advances every year, and we should strive to stay updated with it. With the above steps, you can now lower your machining cost with ease.

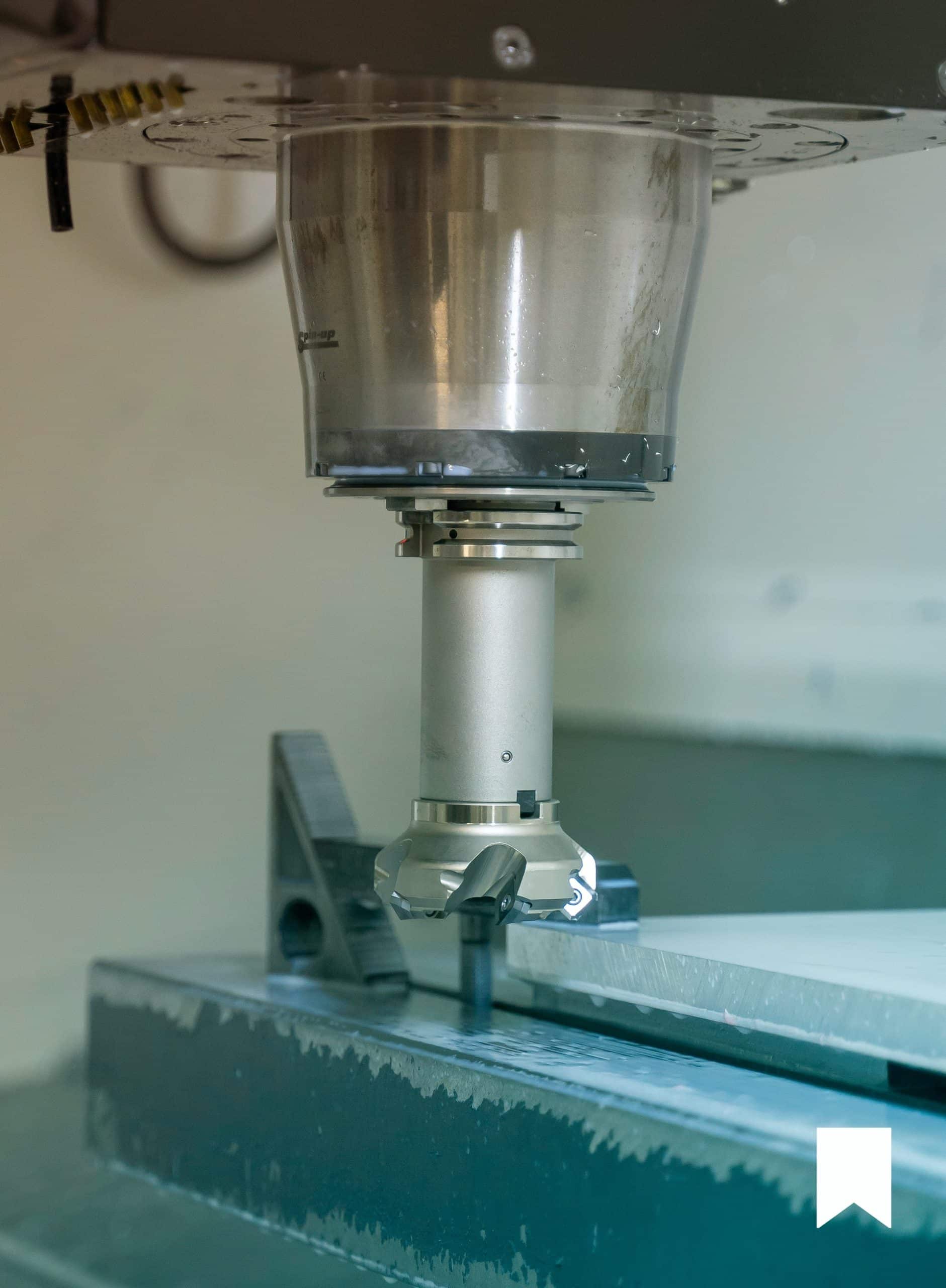

IMAGE: UNSPLASH

If you are interested in even more geek-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS