I know what you are thinking – there is no such thing as 4D printing, but there is. This method of printing objects was first brought to our attention by architect and computer scientist Skylar Tibbits when he showcased the process that allows objects to self-assemble. It’s a new approach to 3D printing that could have an even greater impact on human society than what we could ever expect. When looking further into the technology of 4D printing, we see a whole new set of tools emerge.

When I first heard about 4D printing, I was, as everyone else probably is, skeptical. I thought it was just a way to grab the public’s attention. But when I looked further into it, I realized this way of printing objects is a whole lot more usable and straightforward than 3D printing sometimes is.

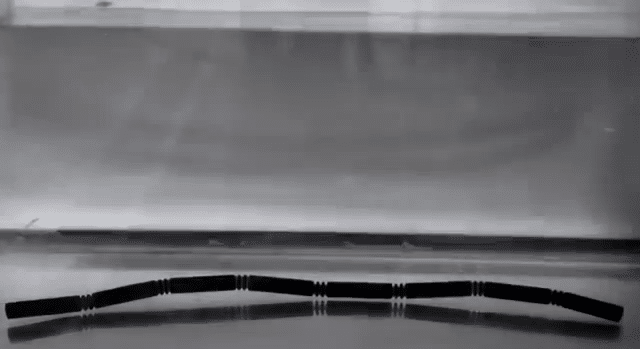

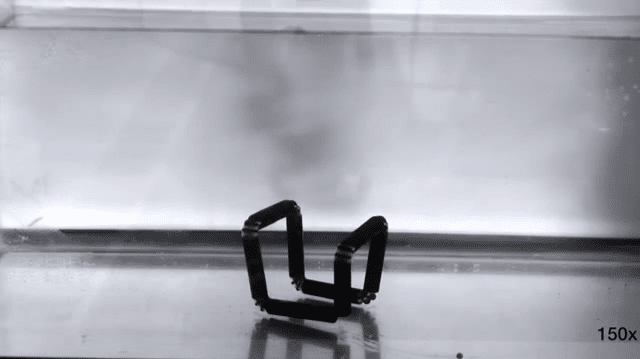

What 4D printing basically means is that the creator prints long tubes that have been prepped with certain joint rules, which make the tube turn into whatever the creator wants it to be once it comes into contact with water. What you have is a 3D printed object that basically assembles itself. The process is still in its infancy, but Skylar has managed to create a tube that when dropped into water turns itself into a cube.

Scientists and architects are currently looking at the material (which is standard plastic with a layer made from a “smart” material) to determine whether they can pre-program the joints with the direction and degree of bending the tube. When the rules are completely mapped out and put into a computer system, we’ll have a 4D printing process that will allow pretty much everyone to print their own self-assembling objects. This is particularly useful for broken pipes underground as well as for space exploration where sending large and bulky objects into space can cost millions. The question is whether or not 4D printing will ever become more “creative” and “versatile” than 3D printing currently is. I guess that is something for consumers to decide, right?

COMMENTS