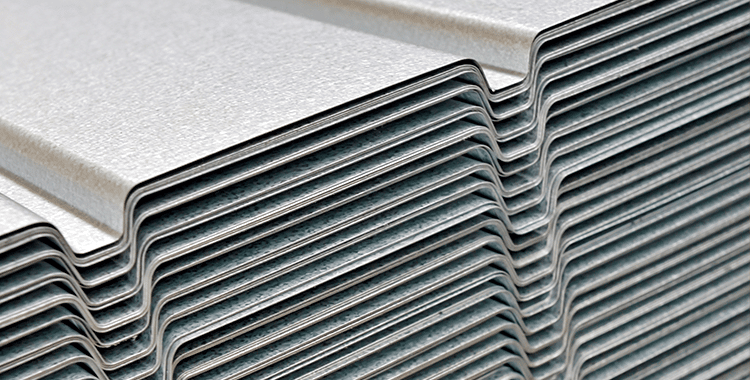

Cold rolled steel and galvanized sheets are equally popular among customers from building companies and huge enterprises. As of today, galvanized steel roofings and construction units are very popular.

Besides, they are OSHA approved, which is a confirmed indicator that requires the necessary implementation. But others stick to a cold-rolled method, claiming that this way, products will serve longer and have less problems with withstanding seasonal issues, such as rains or hails. But, on the other hand, galvanized still is less prone to rusting. So what would you choose?

IMAGE: PIXABAY

Galvanized Steel Sheets

Galvanization is a process of protection products from corrosion by putting a thin layer of zinc over a raw material. But even such protection is not complete if the material is operated in a negative environment. Zinc is subject to its own corrosion, which is called the white rust.

That is why it is better to use a galvanized sheet for conditions of high humidity. In addition, the appearance of the workpiece is much improved with the help of galvanization. You can select zinc infusion in accordance with other materials, if necessary. Galvanization can be held differently: from hot dipping into zinc solution to spraypainting it with zinc.

The difference should be reasonable and understandable. The deeper zinc gets into the steel, the more time it would be there. Usually, a sheet of galvanized steel can remain in a perfect condition for up to two years. Placing a layer of zinc on top shpuld help too, but it would be a different result, although good as well. Galvanized steel is one of the most popular building materials.

Especially it is popular when used in a roof covering, in drainage systems, chimneys, canopies and curtain rods. The zinc coating serves to protect the metal from adverse external influences (precipitation, automobile exhaust gases, ultraviolet radiation, salts and other negatives), extending the service life of metal structures that are mainly operated outdoors, constantly exposed to negative environmental influences.

But the zinc layer is also susceptible to corrosion, however, much less than usual steel. Over time, white rust, which is a white porous substance through which moisture and oxygen begins to easily get to the steel sheet occur, therefore galvanizing itself needs additional protection. The most effective and simple solution is the application of paint formulas.

Cold-Rolled Steel

Cold rolled steel is basically hot rolled steel that has undergone further processing. The steel is processed in cold rolling mills, where the cooled material (at room temperature) is subjected to plastic deformation, which is by annealing.

This method is better because is evidence the surface tolerance which is better for thequality and beauty of the product. Cold drawing makes the metal more strong and flexible, which is better because you will need heat treatment anyway.

Also, it eliminates surface defects, narrows the tolerance range, improves polished surface finish. Such products provide excellent aesthetics value, and are better when it comes to flexibility and straightness compared to hot rolling method. Want to know more? Visit https://metinvestholding.com/products/long-products/round-and-square-steel-bars for additional information.

If you are interested in even more lifestyle-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS