A business needs to be adept at managing its inventory and would benefit a lot from developing an inventory control system. This inventory control system should account for customer demand effectively. Customer demand for a business’ product can influence inventory costs, carrying costs, ordering costs, and storage costs.

A push system and pull system are two general classifications of inventory control systems. Most inventory control systems will fall into one of these two categories. The difference between these systems is how much of a product your business will order or manufacture. Both have big impacts on a business and both have their advantages and disadvantages.

IMAGE: PEXELS

What Is A Push System?

Push systems are systems where your business orders or manufactures products with the aim of selling. Your business pushes its existing stock on the buyer.

A push system is like an Enterprise Resource Planning (ERP) or a Material Resource Planning (MRP) system. A push system will look at demand, analyze the data, make predictions, and then tell you what products to make or order, when, how many, and the completion date. The schedule you follow or activities you have to do are “pushed” down from an ERP to the production floor or purchasing department. This process is very rigid.

In a push inventory control system, forecasting is an essential element. Your business will predict how many of each product it needs for a particular business cycle – month, quarter, or year. Your business will order all its products according to its predicted needs.

One advantage of using a push system in your business is that you are pretty much guaranteed to always have products in stock for customer orders (possibly received through a virtual phone service). Having stock always on hand is crucial for a business and enhances customer service.

Another advantage of a push system is that it reduces manufacturing costs. Most manufacturers charge a fee for every order submitted. However, because you know how much you need for the next cycle, you can order all your products with just a single order.

One disadvantage, however, is that a push system increases the chances of building up excess inventory, especially if you don’t keep watch on existing inventory. Another disadvantage of a push system is that it lacks flexibility. This is due to its reliance on planning in advance.

Example Of A Push System

What is website bounce rate, and what is a push system? Let’s use an example of an eCommerce business that sells household appliances to illustrate website bounce rate and the use of a push inventory control system. As long as this eCommerce business hasn’t made mistakes, it should have a steady stream of orders.

This eCommerce business has reliably sold 200 dustpans every week for three years. In the final quarter of the year, the business sells 30% more than this number. Because of this increase in sales, the business forecasts sales of 3,120 dustpans. The business promptly orders 3,120 dustpans from its manufacturer.

However, the actual customers’ orders end up being 3,100 dustpans, which the business can now sell for a better profit and not worry about the website bounce rate.

What Is A Pull System?

The crucial definition of a pull inventory control system is that if you request what you strongly think you need, there is very little chance you will build up excess inventory or “work in progress”. A pull system involves making requests on an as-needed basis.

A pull system means that your business will request or order products as they are needed. This system forms the basis of the Kanban system. The theory behind using a pull system for inventory control is that, by only requesting or ordering stock when you need it, you won’t build up excess inventory or work in progress.

Some advantages of a pull system are that it gives you more flexibility, helps you reduce the amount of work in progress, and helps reduce inventory (potentially).

However, a pull system does have some disadvantages. One disadvantage is that it can be hard to implement, and, when you do, it can create a lot of chaos since it can expose other problems that you have.

The book The Toyota Way explains this concept of chaos when implementing a pull system. Businesses need to be ready to deal with those problems and fix them in order to get the benefits of a pull system. This is something to communicate with your remote team.

The biggest potential disadvantage is that a pull system just may not work for your business in your specific environment. Imagine a mechanic, for example, where every job may require different parts every time. This makes it difficult to use a pull system because what are you pulling? What are you requesting? The “pulls” can be different every time.

Due to the fact that “pulls” may be different each time, this system works best when you are clear on what you’re pulling and requesting.

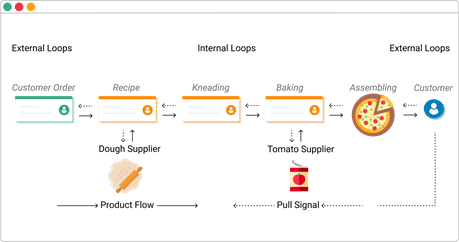

IMAGE: KANBANIZE

Example Of A Pull System

Let’s use an example of a car manufacturing business to illustrate the use of a pull inventory control system. This car manufacturer wants to reduce the number of tires in its warehouse due to the fact that they take up space and pose a serious fire hazard risk.

This car manufacturer makes 200 cars a week, and it takes two weeks to receive tires from the tire manufacturer after orders are placed. The car manufacturer calculates that it will need 3,200 tires in its first order and then 800 tires every week after that.

After four weeks, the manufacturer will be out of tires but then receives 800 new tires every week after that. This supply is enough to meet the manufacturer’s needs.

Work In Progress In Push Versus Pull Systems

In both a push system and a pull system, you will have work in progress (WIP), but how it works will be different for each inventory control system.

If you are using a push system, then you will not place any limit on WIP. Let’s use an example of a manufacturer that makes blenders. You can make as many blenders as you want in order to prepare for a future order. However, you may run out of things to do, so you make more blenders even if there are no orders. Or, when there is an order, but the order prediction may not be fully accurate, an excess inventory of blenders is made to make up for the uncertainty.

If you are using a pull system, then you will typically place buffers which place limits on WIP, so nothing is made unless it’s needed. Return to the blender manufacturer example. You have a small stock of 10 blender lids, and, when you are making blenders, you use five of those lids. When you remove those five lids from the stock, the pull system will trigger an order for five more lids to be made so as to refill the stock.

In a pull system, you aren’t just always making things you may not need. You’re only making more inventory when there is no longer the needed quantity in stock.

Should Your Business Use A Push Inventory Management System?

A push system may be a good fit for your business if it meets the following criteria:

- Your business is older than one year: without previous data, your business won’t be able to accurately forecast demand.

- You have enough profit to cushion unforeseen mishaps: if predictions don’t end up being accurate you will need some cushioning to soften the blow.

- Your sales volume is high: to offset the impact of excess inventory you need to have good sales volume.

- You have high manufacturing fees: being able to place bulk orders will save you from high order fees.

Push systems are usually better for larger businesses that have a good grip on inventory and demand.

Should Your Business Use A Pull Inventory Management System?

A pull system may be a good fit for your business if it meets the following criteria:

- You have a minimal storage facility: if you don’t have space for excess inventory, then a pull system can help control how much storage you need.

- You’re low on working capital: if you don’t have the capital to place large volume orders, the pull system can help spread out costs.

- You’ve been in business for less than 12 months: a pull system doesn’t need a large data set for forecasting. You need less capital to waste on inventory you can’t sell.

- Your clientele is small: having a product that sells fast means you can worry a little less about not selling inventory.

- You work with a local manufacturer: having a local instead of an international supplier means you can replenish stock faster and without high shipping costs.

Most businesses can use and benefit from a pull inventory management system.

Conclusion

Whether a pull system or push system is best for your business will depend on your individual business, its circumstances, and its needs. Some businesses even use a hybrid push-pull system. Additionally, using the right tools such as integrating your business phones for small business on your inventory system is also advisable to support robust communication and collaboration.

You need to know what each inventory control system is and how it may benefit your business, which we have taught you. The decision of which one to use is now up to you.

IMAGE: PEXELS

If you are interested in even more business-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS