If it weren’t for production line automation, North America’s manufacturing industry might have gone extinct due to fierce competition from countries where labour is cheaper and factories face less regulation.

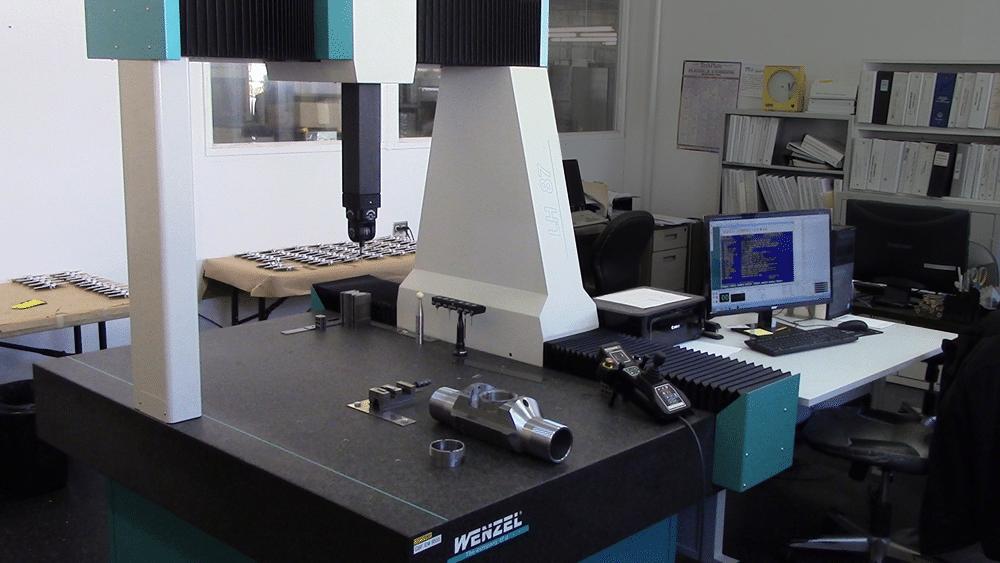

Automation refers to the phenomenon of machine labour replacing human labour. Automation resulted in improved production line efficiency and reduced labour expenses. One of the most common machines used in this process of automation is the coordinate measuring machine, or CMM.

CMM machines measure the physical geometrical characteristics of an object either manually, using a human operator, or through running a computer program. The machine has the blueprint of the parts or objects it scans. Then, a probe on the third moving axis scans these parts or objects and compares it to the blueprint: if there is any difference between the blueprint and the parts themselves, the machine knows the product is flawed. This is what makes CMM machines so well suited for performing quality control tasks on the production line.

There is a range of different machines available, so you can learn about the latest CMM technology here, or read on to get some basic facts about four of the most popular kind of CMM machines.

IMAGE: ROMER

1. Bridge CMM

Bridge CMMs have been the mainstay of coordinate metrology since the 1970s, and they’re still the most common CMM machine in use today. Bride CMMs are so popular because they can handle a wide range of part sizes. They are renowned for their precision and reliability, and come at a price point that provides an excellent value.

2. Portable CMMs

Perhaps most famous among the portable CMM machines is the ROMER Arm, which is designed to perform quality control, inspection, on-machine verification, virtual assembly and 3D modelling. These are rugged and accurate machines, which have an arm that deftly moves around the part or product, so it can measure the dimensions on all sides.

Portable CMMs are able to reverse engineer blueprints from already existing parts. Its integrated scanning system permits inspection right on the shop floor. It collects thousands of data points per second using a white light or laser system. Importantly, it can be used by anyone, anywhere, with very little training.

3. Vision And Multisensor Systems

CMMs need to be scanned using a Vision and Multisensor System if they have parts that are too small or delicate to be scanned with a tactile probe. Some parts are just too small to be measured through physical contact. In this case, video scanners and white light scanners measure parts less than 600 millimetres squared in area, and smaller than 200 millimetres tall.

4. Gantry CMM

Gantry CMM machines are just like Bridge CMMs, only they scan much larger parts. They are commonly used by the automotive and aerospace industries because these production lines produce parts for cars, planes, and even spaceships.

Gantry CMM’s open access to the measuring volume makes it easy to load parts either by crane or lift truck. These machines also require very little maintenance — guideways and drive systems are at a safe distance from contaminants and dirt.

The products that your factory produces will largely shape what kind of CMM you need, but there are other kinds of models, too — speak to a CMM specialist today to find out what specific equipment you need to get the benefits of a CMM machine in your factory.

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS