The PCB manufacturing industry has been undergoing a lot of development trends. With the development of technologies like 5G, Artificial Intelligence, and the Internet of Technology, the PCB development process has new trends. The 5G technology network delivers high speed and steady connectivity to the users, which is much higher than the 4G and other previous networks.

Similarly, IoT technology has added automated and smart technologies in different industries. Human augmentation technology has enhanced human productivity through wearable devices like chip implants, prosthetics, and eyeglasses.

The demand for printed circuit boards rose in the wake of the pandemic. With the crunched supply chain, the PCB industry has worked hard to deliver the most advanced products under the tightest of restrictions. As a result of these developments, the global PCB market may reach around 70-75 billion dollars by 2023.

Read this blog post to know some of the trend of PCB manufacturing that are driving the current PCB industry are.

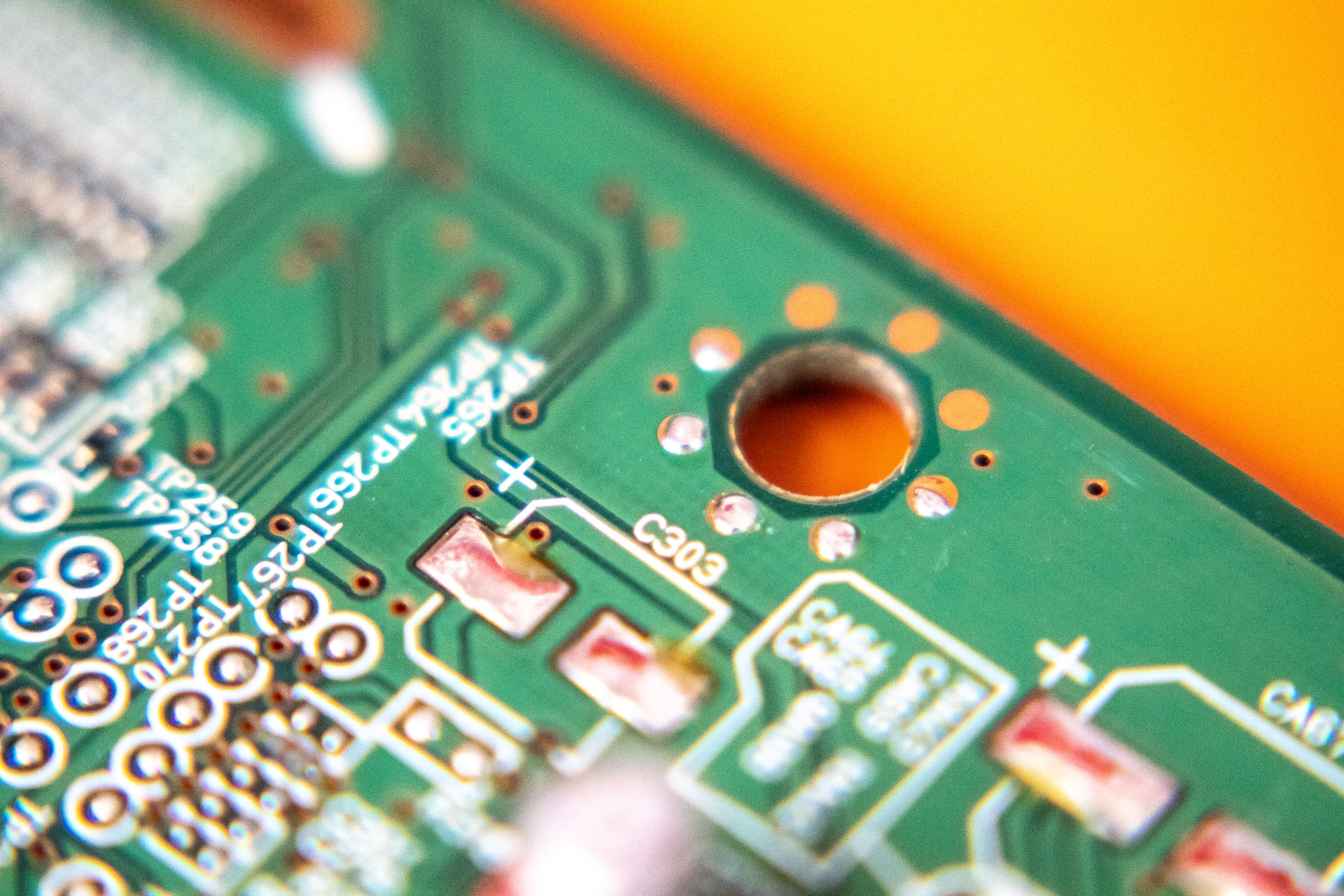

IMAGE: UNSPLASH

3D Printed Circuit Boards

3D printed circuit boards have become a crucial part of 3D printed electronics, transforming the electrical systems designs. 3D printed electronics build a 3D circuit through an additive manufacturing process where you can print a substrate layer by layer. With 3D printing, you can create rapid prototypes in a short time. You do not need a minimum build volume and create many parts without any assembly process. As a result, you can expand the features of the product.

High-Density PCBs

Another popular trend in PCBs is high-density interconnect PCBs or HDI PCBs. It means the PCBs with high wiring density. This is one of the fastest growing technologies as it provides tiny laser vias and pads and compact wiring. HDI PCBs can accommodate more elements in a small space, and thus they are compact and provide higher signal transmission speed with this technology. As the trend for miniature electronic products increases, these small and lightweight PCBs are in high demand in healthcare, automotive and wearable technology.

Flex PCBs

Another requirement in the PCB industry was to create advanced circuit boards in small packages. This trend led to the most innovative development in PCB manufacturing: flexible PCBs. You can easily curve or move these PCBs without damaging the conductor.

These PCBs have changed the shape, size, design, and weight of electronics, especially consumer electronics, as they can fit in spaces where a rigid PCB can’t. As the subscription for mobile and internet TVs increases, consumer electronics are in high demand. All these electronics need precise, versatile, and compact PCBs. Further, the development of various IoT applications also drives the market for flexible PCBs.

Like the traditional PCBs, these are also available as single-sided, double-sided, multilayer, or a hybrid of flexible and rigid materials. The only drawback is that flex PCBs need precise storage procedures, are expensive, and are more challenging to repair than traditional PCBs. Further, there are high chances of electromagnetic interference between traces and components in these PCBs. Thus, there has been a high demand for built-in ESD protection systems to prevent performance degradation.

High-Power Boards

Another significant development in the world of PCB manufacturing is high power boards. Most modern devices use high power, and thus higher power circuit boards are gaining massive popularity in various industries. The main component of high-power boards is heavy copper, which can handle higher rates than standard PCBs. Further, they can also resist high temperatures for a more extended period. You can find different types of high-power PCBs, such as rigid-flex high-power PCBs, double-sided high-power PCBs, and multilayer high-power PCBs.

Biodegradable PCBs

The exhaustive use of silicon in the PCB industry has led to various toxic substances in the environment. Thus, PCB manufacturers are looking for biodegradable alternatives. The biodegradable PCBs break down within 10 minutes after water exposure as they are made from chicken feathers, banana stems, and wheat gluten. Now manufacturers are also looking for methods to assemble and manufacture biodegradable PCBs.

There has been a high demand for automatic driverless vehicles and electric automobiles. The advanced features of these automated vehicles must address safety, environmental concerns, and safety. Thus, the automotive industry needs a PCB with good heat dissipation capability and superior thermal design.

Other Popular Trends

Apart from these innovations, PCB experts are also looking to create active PCBs. Currently, PCBs are passive components that connect the circuit’s active components. However, if PCB becomes the active component of the circuit, they can function as desired in lesser components. All the industries are currently focusing on AI-enabled solutions, and these AI applications have led to the restructuring of the PCB manufacturing cycle to reduce defects.

All these trending technologies require multilayer PCB fabrication as the multilayer stack up of layers enhances energy distribution and reduces EMI issues. Applications in the medical and aerospace industries need strict control of electromagnetic interference, and cell phone developers also need to minimize the radiation hazards due to electromagnetic waves. Thus, PCBs must comply with EMI regulations. If not, the high-volume boards may result in re-spin.

In addition to the 3D printing that helps make PCB prototypes, another innovation that helps develop rapid prototypes for these smart PCBs is CNC machining and CNC milling. These are subtractive manufacturing processes where you can shape and create different parts of a product or prototypes with the help of complex machinery.

Conclusion

These growing trends increase the speed of the design and development of PCBs. However, it is essential to design, assemble and fabricate the products with extreme care and precision. The latest technological innovations are changing the PCB manufacturing trends. PCB manufacturers will have to build flexible manufacturing processes and a more dynamic supply chain to address the requirements of the new PCB trends.

IMAGE: UNSPLASH

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.