When highly automated computer numerical control [CNC] machines were first being invented, nobody thought that they would eventually have various applications. In the past, the CNC machines were used to automate manufacturing processes to get reduced human error and increase production.

CNC machining has gone beyond the manufacturing sector. Currently, the same technology is even used in manufacturing medical equipment that is used for various purposes such as surgical equipment, dentistry, and artificial muscle joints. The CNC machining from Star Rapid can use automation to copy the exact instructions that are programmed beforehand.

For any medical organization, this is one of the best ways to ensure accuracy, reduced cost, and reproducibility. This article gives you some of the ways that the CNC machine can be used in the medical sector.

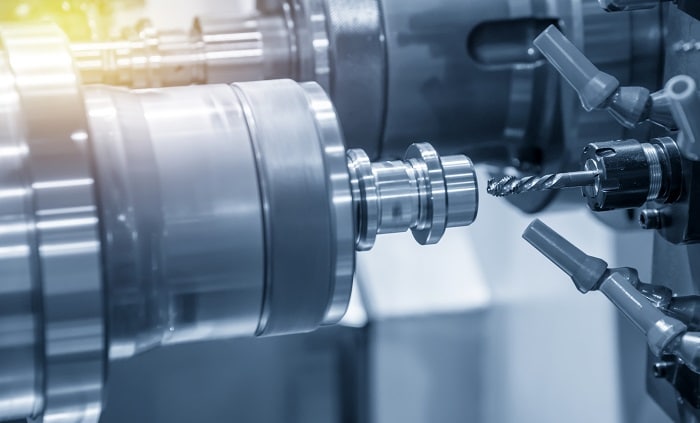

IMAGE: PIXABAY

Quality And Consistency

Not too long ago, people could only try their best to imitate the mechanism of human joints. The ability of CNC machines to operate multiple axes simultaneously has allowed medical design engineers to alter that. Since CNC machine allows for precision part imitation and consistency in even the most complicated surface designs and geometries, medical implants and devices can now be designed with less manufacturing limitations. This encourages quicker innovations in the medical industry as well.

Accuracy and consistency are critical for every single part of medical equipment delivered. Medical products must ensure quality standards and any failure to comply with these standards can create severe problems to the patient. This also applies to items such as surgical items; they must meet certain requirements, including, “feeling right” in the hands of the surgeon.

Lives and livelihoods depend on quality machines for both the equipment used in the surgery and parts implanted in patients.

CNC Machining applications in the medical sector

Through automation, consistency, and high level of accuracy, CNC can now be used in the following medical field to provide better healthcare to patients.

1. Hip Replacement

One of the procedures that have been greatly improved as a result of CNC machining is the hip replacement. Even though the surgery itself is usually successful; there are some few issues with the traditional replacement parts. Hip replacements are wearing out sooner with the rate at which people are living longer and more active lives. Although hip replacement is a very common procedure, getting the surgery done is still a significant decision for many patients. The process is very invasive, and the recovery takes quite a long duration and it is also painful.

The smallest error in the machining of a hip replacement component can make the procedure unsuccessful or cause discomfort for the patient and may call for a second operation. CNC machining, when done correctly, can produce implants that fit perfectly and last longer while reducing these concerns.

2. Dentistry

When it comes to dental treatment, everybody has a different mouth. Dentists usually have to develop precise dental implants, dental aligners, or tooth crowns that can perfectly fit a particular patient. Despite the new 3D imaging technologies that provide an accurate picture of the patient’s treatment plan, dentists still have to design accurate dental products that will provide the desired results. Now, this is where the CNC machine comes in. They can be programmed to get the exact dimensions of the dental veneers, aligners, and tooth crowns that fit a patient with minimal discomfort. Since the entire procedure is automated, the margin of error is significantly low.

3. Surgical Equipment

During various corrective surgeries, the implants that are placed in the body have a low margin of error against failure. For instance, pieces of metal that are implanted to strengthen prosthetic limbs should fix precise dimensions.

Traditionally, manufacturers of medical equipment used to spend significant amounts of time to handcraft this equipment for patients. The computer numerical control machines have made it easier since surgical equipments can now be produced in a shorter amount of time with higher accuracy. But how does the machine work? The exact dimensions of the product required are programmed into the CNC machine, and then the machine takes over to automatically create the final product. The programmer only needs to check for quality control before the patient is fitted with the device.

If you are interested in even more technology-related articles and information from us here at Bit Rebels, then we have a lot to choose from.

COMMENTS